【Gold Ore Beneficiation Technology】Four Common Antimony-Gold Ore Flotation Methods

2025-07-30 Xinhai Views (412)

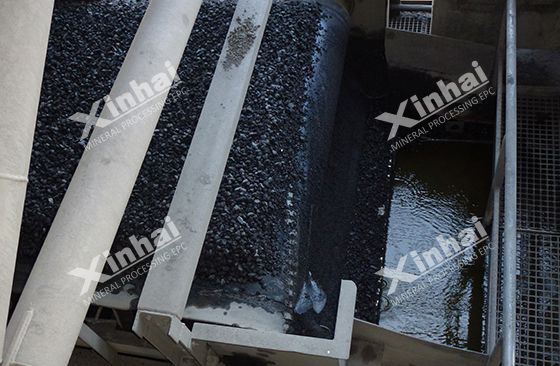

In antimony-bearing gold ores, the main target minerals include stibnite, native gold, pyrite, and arsenopyrite. Pyrite and arsenopyrite are the primary gold-bearing minerals, while some stibnites also contain gold, and arsenopyrite and pyrite contain arsenic. Because the gold in antimony-bearing gold ores is finely embedded and the stibnite consumes cyanide and oxygen, flotation is often used for recovery. In production, in addition to the recovery of coarse native gold using gravity separation, the beneficiation of this type of gold ore focuses on the flotation separation of stibnite from pyrite, arsenopyrite, and other minerals, often employing preferential flotation and mixed-preferential flotation. Depending on the specific reagents used, flotation methods for antimony-bearing gold ores can be further divided into sodium hydroxide, sodium sulfide-sodium hydroxide or sodium carbonate, oxidant, and butyl ammonium black powder.

.jpg)