In early October 2025, the 1.5 million t/a copper ore flotation plant project, a collaboration between Xinhai Mining and a client in Kazakhstan, officially commenced on-site construction. The main plant building construction layout was completed, and the ball mill foundation entered the earthwork excavation stage, marking another benchmark case for Xinhai in the field of large-scale overseas mining EPC projects.

Background of the 1.5 million t/a copper mine project

Kazakhstan, a major global mineral resource country, boasts abundant and diverse mineral resources, with copper resources being particularly prominent—proven copper reserves exceed 30 million tons, primarily in the form of sulfide copper ore, often accompanied by gold, silver, and other precious metals, possessing high development value. In addition to copper, Kazakhstan also ranks among the world's leading countries in iron ore, lead-zinc ore, and uranium reserves, making it a key region for global mining investment. In recent years, the Kazakh government has continuously optimized its mining investment environment, encouraging foreign investment in mineral resource development and providing ample opportunities for cooperation among international mining companies.

Xinhai Mining, a leading provider of end-to-end mining solutions in China, has been continuously expanding its overseas market presence for many years. It has completed thousands of mining projects in over 100 countries and regions worldwide, accumulating rich experience, particularly in resource-rich regions such as Central Asia, Africa, and South America. This 1.5 million t/a copper mine project in Kazakhstan is another large-scale EPC (Engineering, Procurement, and Construction) project undertaken by Xinhai in Central Asia. The project was facilitated through e-commerce channels. After on-site visits to Xinhai's testing center, production base, and existing projects, the client highly recognized Xinhai's technical strength and project management capabilities, ultimately leading to a full-process EPC cooperation agreement.

Overview of the 1.5 million t/a copper mine project

Key parameters of the project

Processing capacity: 1.5 million tons per year, 5,000 tons per day, 300 working days per year.

Work schedule: Crushing plant 16 h/d, main plant 24 h/d continuous operation.

Raw material characteristics: Raw ore with a large particle size of 800mm, moisture content of 5%, and ore density of 2.99t/m³.

Process indicators: Pre-flotation grinding fineness of -0.074mm accounts for 60%, flotation concentrate yield is 3.51%, concentrate copper grade is 22.00%, and copper recovery rate reaches 90.00%.

Project cycle: Construction starts in early October 2025, with two months of on-site operation completed in 2025, resumption of work in April 2026, and completion of civil engineering, equipment installation and commissioning by the end of December 2026. The actual effective construction time is less than one year.

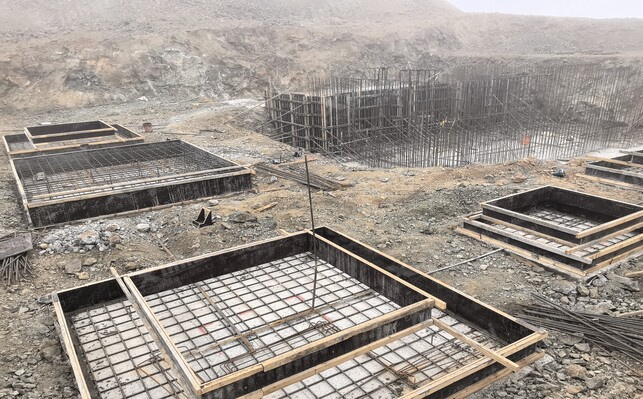

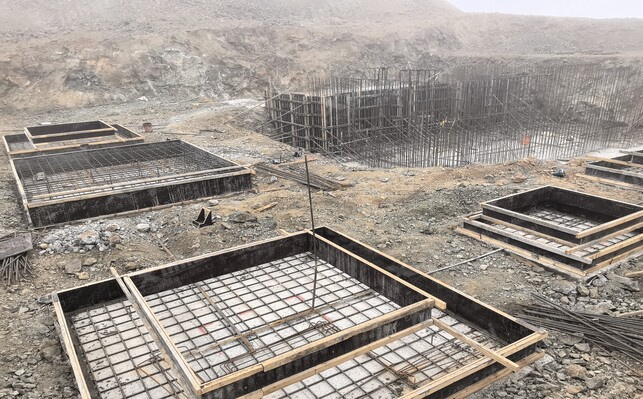

project progress status: as of November 2025, the project had completed preliminary preparations and on-site commencement work.

The main plant layout for the ore dressing plant has been completed, and the site leveling has met standards. Excavation work for the ball mill foundation has commenced, and the foundation pit support plan has passed local supervisory inspection. Major equipment (including jaw crushers, agitation tanks, etc.) has been manufactured and is in the preparation stage, with shipments scheduled to begin after work resumes in 2026. The on-site construction team has completed local construction standard training, and the safety management system has been established.

Xinhai Services - Full-chain Mine Services (EPC+M)

Xinhai Mining Equipment provided the project with a full-process, integrated service, from preliminary experimental research to later production and operation maintenance, addressing all the client's pain points throughout the process. The specific services covered six key aspects:

Engineering Service

Metallurgic Test: At the initial stage of the project, Xinhai Testing Center received raw ore samples from the client and conducted a 15-day mineral processing test. Through ore composition analysis and liberation testing, the dissemination characteristics of the copper sulfide ore were determined. Through multiple sets of comparative tests on grinding fineness, reagent regime, and flotation time, a flotation process of "one stage of coarse grinding + one stage of roughing, two stages of cleaning, and one stage of scavenging" was finally determined. A detailed test report was issued, clarifying all data and providing a scientific basis for engineering design.

Detailed Engineering Design: Xinhai Design Institute assembled a specialized design team to complete a comprehensive design, taking into account local climate, geological conditions, and client needs. This included process design, equipment layout, civil engineering design, and environmental protection design.

Complete Equipment Manufacturing and Procurement

Xinhai Intelligent Equipment Manufacturing Factory covers an area of approximately 110,000 square meters. Leveraging its independent production base, it provides major equipment and auxiliary facilities for the entire process. Major equipment includes crushers, vibrating screens, ball mills, classifiers, flotation machines, thickeners, and filter presses. Auxiliary equipment includes supporting automated control systems, belt conveyors, and reagent preparation systems to achieve fully automated operation of the entire process.

Civil Construction and Installation & Commissioning

Civil Engineering: Xinhai undertook all civil engineering construction, addressing the industry's past shortcoming of "emphasizing equipment while neglecting civil engineering." The scope of work covered all civil engineering works, including the main plant of the ore dressing plant, crushing plant, ball mill foundation, thickener, tailings facility storage, and office building. Experienced civil engineers were dispatched to the site during construction, employing a combination of BIM modeling and on-site measurement to ensure construction accuracy, and a detailed construction plan was customized.

Installation & Commissioning: A professional installation team was assembled for this project, responsible for equipment installation and system commissioning, ensuring rapid project commissioning. Work was carried out according to the principle of prioritizing heavy equipment and main equipment before auxiliary equipment, effectively completing the installation of each piece of equipment with an accuracy error controlled within ±2mm. Commissioning employed separate system debugging and integrated debugging to optimize equipment operating parameters. During commissioning, technical personnel were stationed on-site to guide and train client operators, ensuring the project met design specifications upon commissioning.

Mine Management

After the project reaches its target production capacity, Xinhai will continue to provide ongoing operation and maintenance services, including spare parts supply, technical support, and personnel training, to ensure the long-term stable operation of the project.

The 1.5 million t/a copper ore flotation project in Kazakhstan is not only another benchmark for Xinhai's overseas market, but also has three strategic significances: consolidating its large-scale project capabilities, expanding its market boundaries, and enhancing its brand influence. In the future, Xinhai Mining Equipment will continue to focus on "large-scale projects" as its strategic priority, deeply cultivate overseas mineral resource-rich regions, provide global customers with more efficient and reliable end-to-end mining solutions, and promote Chinese mining equipment and services to the world.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat