Mineral processing plant design is the essential "blueprint" phase before construction, bridging the gap between laboratory test results and industrial production. Mining projects involve massive investments and high risks, so a scientifically sound processing plant design helps clarify the construction plan, control budget and schedule, and ensure stable operation after startup. Industry experts note that "a reasonable mining design can effectively reduce investment, avoid risks, and ensure the stability of production systems." In practice, a well-designed plant can not only lower operational costs and increase recovery, but also ensure safe production and meet environmental standards. Its importance spans the entire project cycle, from investment decision to production.

Necessities for Conducting Mineral Processing Plant Design

A thorough design is critical to a project's success for several key reasons:

1.Economic Rationality

A complete design enables accurate estimation of capital and operating costs. By detailing equipment requirements, civil works quantities and process parameters, the total investment can be forecast precisely. From the design, one can also predict consumption of water, power, reagents and labor to calculate operating costs. Based on the anticipated concentrate production and grade, projected revenue can be estimated. These estimates enable calculation of return on investment (ROI), net present value (NPV) and payback period, determining project viability and avoiding scenarios where the project would lose money.

2.Engineering Guidance

The design provides precise blueprints for construction and procurement. The overall plant layout defines the positioning of each processing area (crushing, grinding, flotation, dewatering, etc.), as well as roads, conveyors and utility networks, ensuring an efficient production flow. Equipment selection calculations determine the exact machinery needed (e.g. crushers, ball mills, flotation cells) with their models, sizes and capacities, serving as the basis for procurement and bidding. The design also provides load and dimension requirements for all foundations and structures, ensuring structural safety. By providing these detailed plans and specifications, the design ensures construction quality and avoids costly rework.

3.Risk Avoidance

A well-prepared design minimizes technical and financial risks. Technically, it reduces the chance of selecting an inappropriate process flow or equipment that would later require costly modifications. Financially, detailed budgeting and schedules prevent overruns and investment failures. Additionally, modern designs explicitly include safety and environmental measures (such as tailings containment, wastewater treatment, dust suppression and noise control) to meet regulatory requirements. These measures are prerequisites for obtaining permits and legal operation, and they help prevent future safety incidents and environmental penalties.

4. Optimization and Future-Proofing

Professional designs incorporate forward-looking optimization. For example, contemporary designs should integrate plans for automation, online monitoring and intelligent control systems, laying the foundation for a future “smart” plant. Designs should also allow room for future expansion or technological upgrades. As industry experts note, designs should anticipate future technical improvements and capacity increases so that the plant can be scaled or modified as market demands change.

Xinhai Mine Design Process

Mineral processing plant design is carried out in multiple stages, each with a specific focus, together forming a complete design system. Common types of design work include:

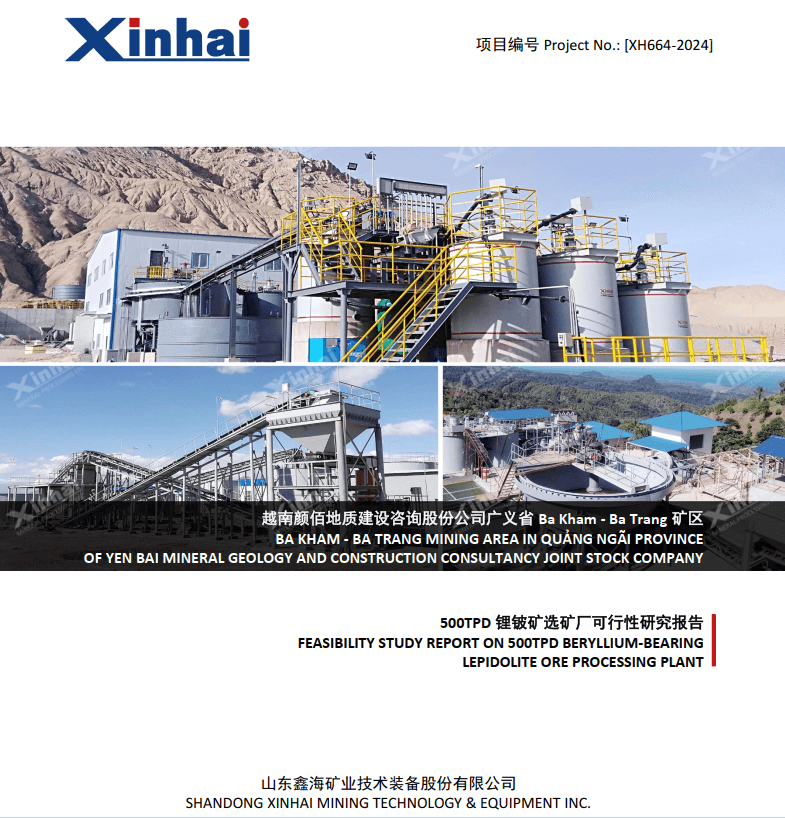

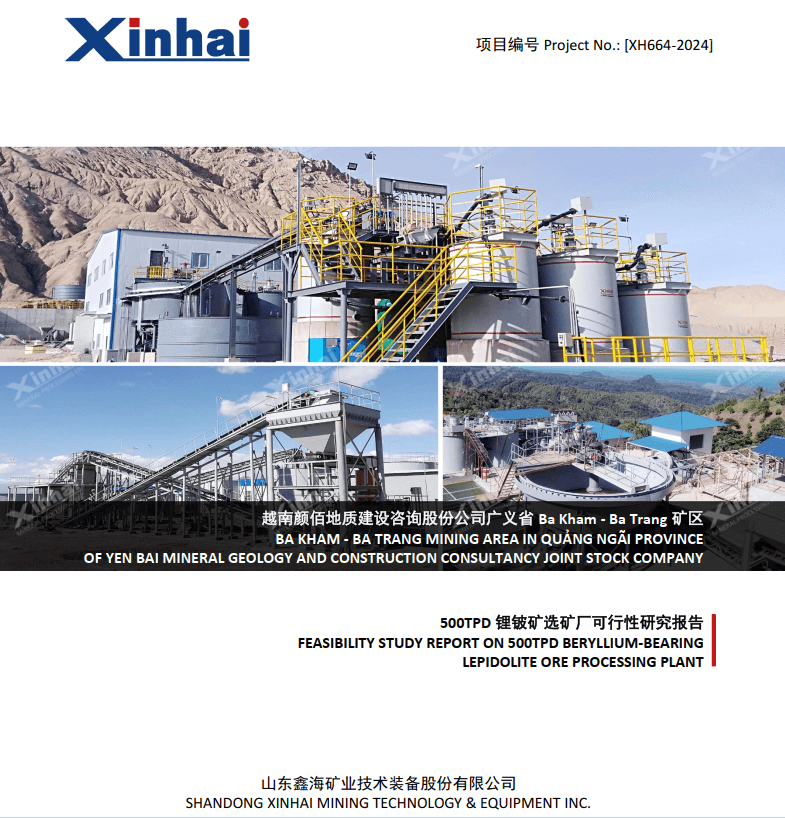

1.Feasibility Study

Conducted during project approval and planning. The feasibility study evaluates ore supply conditions, processing options, product targets, and market demand in detail. It includes both technical and financial analysis to estimate total investment and forecast economic returns. The feasibility report serves as the basis for investment decisions and project approval. It typically covers site selection, construction conditions, alternative process flow comparisons, target production and quality, and preliminary equipment selection.

2.Preliminary Design

Carried out after the feasibility study is approved. Preliminary design transforms the high-level feasibility plan into a detailed engineering scheme. It includes process flow diagrams, plant layout, equipment lists, power and utility systems, civil works, tailings management, and safety systems, along with a preliminary investment estimate and economic evaluation. Based on the mining and processing plan, the preliminary design optimizes the arrangement of crushing, grinding, flotation and other processing circuits, selects all major equipment models and capacities, and compiles accurate material lists, resulting in a finalized Preliminary Design.

3.Safety Facility Design

Due to the inherent hazards and environmental requirements of mining, a dedicated safety design is produced as part of the overall project design. This specialized study focuses on ensuring safe operations by identifying potential hazards and specifying protective measures. It typically covers tailings dam safety, water and dust control, fire prevention, ventilation and other safety systems. The safety design addresses these concerns in detail.

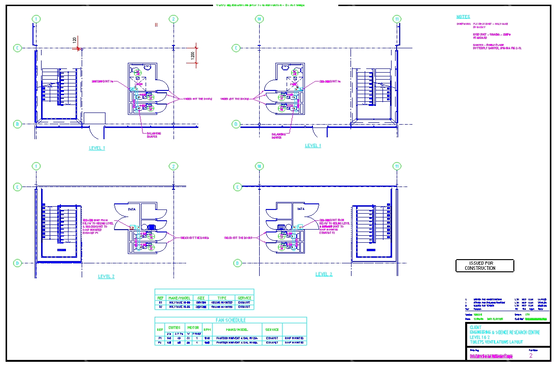

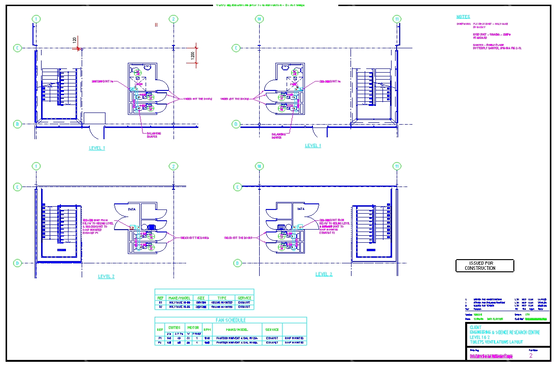

4.Construction Drawing Design

Also known as detailed design or shop drawings. In this final design phase, the approved preliminary design is expanded into full engineering blueprints. Construction drawings include detailed plans for equipment installation, structural and civil works, piping and cable layouts, etc., to guide on-site construction. Based on the approved preliminary design, the construction drawings specify the exact construction methods and technical requirements for each production and auxiliary system. These detailed blueprints guide the work of all engineering disciplines (civil, electrical, instrumentation, etc.), ensuring the project is built according to plan.

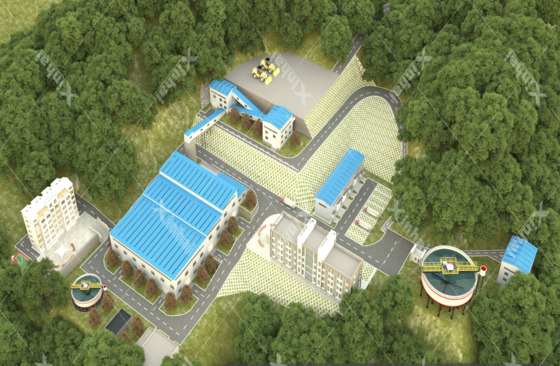

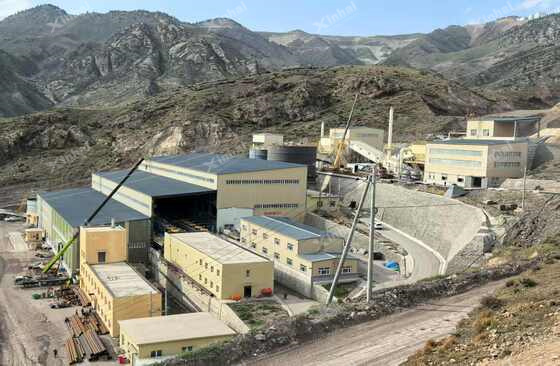

Partial Xinhai Design Cases

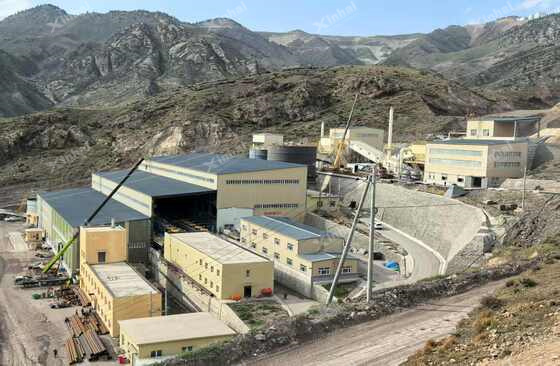

China Xinjiang 2 Million t/a Gold Renovation and Expansion Flotation Plant

Zimbabwe 2 Million t/a Spodumene Ore Processing Plant

Indonesia 2 million t/a Limestone Project

Mozambique 10,000tpd Heavy Sand Wet Separation Production Line

Mongolia 3,500 t/d Iron Tailings Mining and Processing Plant

In summary, a comprehensive mineral processing plant design is not only a feasibility demonstration, but also the fundamental basis for maximizing investment returns, ensuring safe and efficient production, and enabling sustainable long-term development. For mine owners and investors, allocating adequate time and resources to the design phase is a key step toward ensuring a processing plant project's success.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat