Xinhai Mining is a leading supplier of ore concentration and beneficiation equipment, offering complete EPC M+O(engineering, procurement, construction, management, and operation) solutions built on 30+ years of R&D and global experience. With hundreds of mineral processing projects worldwide, Xinhai continually advances its technology and patents to deliver highly efficient, energy-saving equipment. The company’s commitment to innovation is reflected in its customized designs and new features across its product line.

In this article, we highlight five key Xinhai products – ball mills, thickeners, flotation machines, slurry pumps, and hydrocyclones – covering their applicable ores, available configurations, technical advantages, and real-world applications.

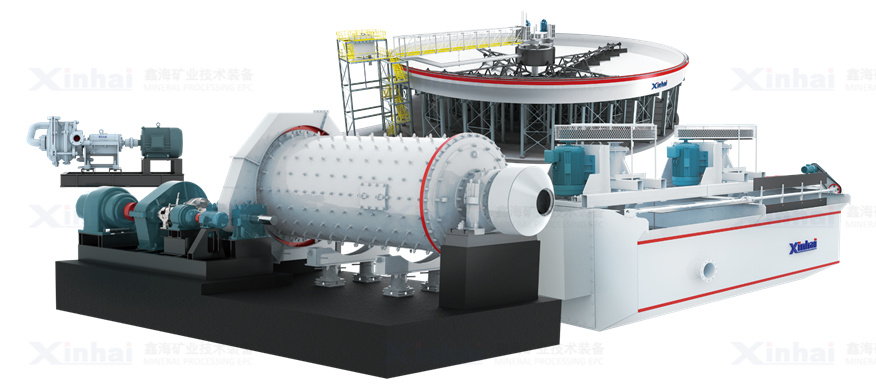

1. Ball Mill

Ball mills are the backbone of grinding circuits in concentrators. Xinhai’s ball mills are designed for high efficiency and low energy consumption. They grind a wide range of ores – including gold, copper, iron, lead-zinc, molybdenum, and others – to achieve the fine particle size needed before downstream concentration processes.

1.1 Models and Configurations: Xinhai offers multiple ball mill types: energy-saving overflow mills, grid (grate) mills, and rod mills. Mills can be customized by diameter, length, and drive system to match processing scale. Available configurations include single or dual drive motors, closed-circuit with hydrocyclones, and batch or continuous feed.

1.2 Technical Advantages: Xinhai's mills feature a groundbreaking permanent-magnet synchronous motor drive system that replaces traditional geared reducers. Key innovations include:

Direct-drive high-torque motor: Eliminates the gearbox, improving mechanical efficiency and raising the overall drive efficiency by 10–40% The motor meets IE4 energy standards and provides stable start-up torque (>1.8× rated), reducing startup impact.

Variable-frequency control: Adjusts mill speed to optimize grinding under varying loads, with vector control for low startup current (no grid shock).

Compact, low-noise design: Smaller footprint (no reducer) and high power factor (0.94–0.99) reduce space, vibration, and power line losses.

Intelligent monitoring: Embedded temperature and vibration sensors enable real-time health monitoring, early warning and self-protection. The drive supports IoT and remote operation, enhancing safety and reducing maintenance.

1.3 Cases Applications: Xinhai energy-saving ball mills have been used in numerous concentrators. For example, a 500 tpd gold CIP plant in Zimbabwe employs an Xinhai energy-saving ball mill in its closed-circuit grinding system. The combination of the ball mill with Xinhai’s hydrocyclone classifiers and agitators ensures high throughput and stable grind size in practice.

2. Thickener

Thickeners consolidate slurry and recover process water in flotation and tailings circuits. Xinhai’s thickeners are engineered for fast settling and high underflow density across many ore types (gold, copper, iron, polymetallic, etc.). The company addresses common issues of conventional thickeners (slow settling, “muddy” overflow, low capacity) with innovative features.

2.1 Models and Configurations: Xinhai provides three main thickener types: ordinary circular, high-efficiency deep-cone, and rectangular box (paddle) thickeners. These can be equipped with either mechanical rake drives (motor + gearbox with overload protection) or hydraulic drives. Thickeners can be built with steel frames for modular transport, and with optional tilt-plate modules for increased compaction in limited-area installations.

2.2 Key Innovations: Xinhai thickener designs incorporate multiple patented improvements:

Degassing and defoaming: Specialized degassing tanks or defoaming tubes remove air bubbles from feed slurry, preventing froth retention at the interface and boosting settling rate.

Optimized feed system: The feed pipe is placed below the overflow level (in the feed well) to avoid suction air and agitation. An added feed tray or distributor gently spreads slurry, minimizing turbulence and “muddy” water.

Zigzag overflow launder: Breaks up negative pressure differences in overflow, reducing local suction short-circuits. Internal baffles and multi-stage overflow paths lengthen particle travel for more complete settling.

Deep-cone design: The high-cone thickener uses a steep cone angle and tall cylindrical section, allowing up to ~75% solids underflow. Compared to traditional thickeners or filter-press systems, deep-cone units increase concentration by ~30% while cutting capital and operating cost up to ~40%.

Curvilinear rake arms: Replacing straight rake teeth with curved arms pushes slurry centrally, wringing out excess water and boosting underflow density and capacity.

Tilt-plate modules: Inset inclined panels shorten settling distance (shallow-settling theory), so fine slurries reach compaction quickly, enabling higher throughput per area.

Flexible drives: Customers can choose a simple electric rake (mechanical) or maintenance-free hydraulic motor drive depending on control and footprint needs.

2.3 Cases Applications: Xinhai thickeners are used in global mineral plants. Notable examples include 1200–6000 tpd gold and silver processing plants in Africa and Asia. For instance, Xinhai furnished thickeners for a 6000 tpd gold plant in Guinea, a 1200 tpd gold plant in Tanzania, and similar scales in Zimbabwe and Malaysia. These installations benefit from Xinhai’s high-efficiency design to handle large slurry volumes with reliable, clear overflow and thick underflow.

3. Floatation Machine

Flotation machines (froth cells) are the heart of ore beneficiation equipment for sulfide and precious metal recovery. Xinhai – one of the world's largest flotation-cell manufacturers – produces a full range of agitator cells. Their flotation machines serve non-ferrous ores (Cu, Pb-Zn, Ni, etc.), ferrous metal sulfides, gold-bearing ores, industrial minerals (fluorite, scheelite, etc.) and more.

3.1 Models and Configurations: Xinhai's flotation lineup includes air-inflation and mechanical cells in many designs:

KYF Air-Inflation Cells: Large-volume, stair-mounted flotation tanks (impeller-driven aeration).

XCF Circular Self-Priming Cells: Circular tank with self-aspirating impeller and stator (negative-pressure suction) allowing horizontal installation without external pumps.

SF Mechanical Flotation Cells: Submerged impeller cells (similar to Denver D-12 type) for strong agitation.

JJF/Wemco Cells: Submerged impeller machines (Wemco type) for fine control in combined circuits.

BF Column Flotation: Tall column cells for fine particle or scavenging flotation.

XCF-KYF Combined Units: Integrated units using both cell types to optimize performance.

3.2 Technical Advantages: Xinhai flotation machines offer several performance improvements:

Energy-efficient design: The patented circular XCF cell has no dead corners (unlike square cells) and uses special geometry, cutting power consumption by 15–20% at equal capacity. Overall recovery can improve by 1–3% with Xinhai’s energy-saving cells, and concentrate grade by 10–35%.

High recovery and stable froth: Strong agitation and uniform air distribution create rich, fine-bubble froths. For example, KYF cells deliver high flotation indices with 30–50% energy savings.

Self-priming capability: XCF cells generate negative pressure to draw slurry into the impeller, eliminating the need for external “froth pumps”. This enables fully horizontal layouts and easier retrofits in existing plants.

Automation and safety: High-automation features (automatic level control, pneumatic systems, lubrication) reduce operator labor. The enclosed tank design prevents dust/gas escape, improving environmental and operator safety.

3.3 Cases Applications: Xinhai flotation equipment has been deployed in numerous mines worldwide. In a Vietnam gold plant (120 tpd), Xinhai supplied SF flotation machines for roughing, concentration and scavenging stages. In copper-lead-zinc plants, combined KYF+XCF banks are common for multi-stage recovery, leveraging horizontal installation and reduced capital cost. Overall, Xinhai flotation cells deliver reliable, high-efficiency separation in diverse ore flows.

4. Slurry Pump

Slurry (pulp) pumps are essential ore concentration equipment for transferring abrasives: they move ore slurries through grinding circuits, classifiers, thickeners, filters and more. Xinhai’s slurry pumps are built for heavy-duty service with wear-resistant materials.

4.1 Applicable Slurries: Xinhai pumps handle a wide range of mill and plant slurries. Typical applications include gold, silver, copper, iron, lead-zinc, molybdenum, and other metallurgical pulpsxinhaimining.com. They convey high-solids slurries (up to ~65% solids) from grinding mills to cyclones, between flotation stages, or from thickeners to filtration.

4.2 Models and Configurations: The product line includes:

Double-Stage (High-Head) Slurry Pumps (XPA(2) Series): Two impellers in series allow high lift (up to 70 m head) without increasing impeller diameterxinhaimining.com.

Wear-Resistant Slurry Pumps (XPA Series): Conventional single-stage pumps with rubber- or alloy-lined casings for abrasion resistance.

High-Head Long-Distance Pumps: Extended frame pumps for elevated discharge heads (up to ~40 m or more).

Alloy Lined Pumps (WPA Series): Metal-lined versions for high-temperature or very abrasive slurries.

Submerged Slurry Pumps: Designed for pit dewatering or submerged duty.

4.3 Key Advantages: Xinhai slurry pumps incorporate several features for durability and performance:

Double-Impeller Design: The XPA(2) double-stage pumps break the usual 60 m head limit, achieving up to 70 m head. This is ideal for processes needing high lift without multi-stage piping.

Ultra-Wear Liners: Impellers and casings use Xinhai’s own high-wear No.35 rubber formulation. In practice, this yields 2–4× the service life of equivalent metal pumps, dramatically reducing downtime.

Reliable Sealing: Packing glands (or optional mechanical seals) provide leak-free operation. The design allows quick replacement of wear parts (impellers, liners) with minimal disassembly.

Corrosion Resistance: Rubber lining also resists chemical attack in acidic or cyanide-containing slurries, making pumps suitable for gold-CIP/CIL circuits.

4.4 Cases Applications: Xinhai slurry pumps have proven in many mining projects. For example, wear-resistant rubber pumps are installed at the Zimbabwe 500 tpd gold CIP plant and the Sudan 240 tpd gold plant. Double-stage XPA(2) pumps are used where high lift is required. These pumps deliver reliable service in grinding, classification and tailings duties across Xinhai’s global projects.

5. Hydrocyclone

Hydrocyclones are compact classifying and thickening cyclones widely used after grinding and in tailings dewatering circuits. By centrifugal force, they separate fine and coarse particles, reducing processing loads downstream.

5.1 Applications: Xinhai hydrocyclones serve multiple roles: as classifiers to remove fines in grinding circuits, deslimers to isolate slimes, and thickeners/dewatering cyclones for tailings. They’re used with virtually every ore type processed (gold, copper, iron, nonferrous concentrates, etc.). For example, in a 500 tpd gold CIP plant (Zimbabwe), a cyclone unit was used in the closed grinding loop to recirculate mill overflow to thickening.

5.2 Models and Configurations: Xinhai's cyclone series includes:

XCI Series: Standard classifiers/dewatering cyclones (for normal classification duties).

XCII Series: Thickening cyclones engineered for high underflow concentration (used in tailings dry-stack circuits). These can achieve underflow solids ~75%.

XCIII (Patented “Fish-Tail” Cyclone): Incorporates a fish-tail feed connection and siphon device to adjust overflow density. In quartz sand plants it can push overflow solids as high as ~85%, effectively maximizing dryness.

XCIV Series: Fine-particle classifiers for specialized dewatering and extreme fines separation.

5.3 Key Advantages:

High Efficiency, Small Footprint: Cyclones provide very high classification efficiency in a compact unit. Multiple cyclone units occupy far less space than equivalent multi-stage screens or thickeners.

Adjustable Density: Patent features (siphon, overflow clamps) allow fine tuning of concentrate or underflow density. Xinhai’s thickening cyclones discharge very dense underflow (≈75%) and ultra-dry overflow (as low as ~3% solids in quartz processing).

Durable Construction: Robust rubber/ceramic lining options resist abrasive wear. Modules are easy to install and replace, simplifying maintenance in the plant.

5.4 Cases Applications: Hydrocyclones are integral to many Xinhai plants’ circuits. As noted above, the Zimbabwe gold plant’s grinding circuit used a classification cyclone to feed a thickener. Similarly, Xinhai’s Mali gold project and others use XCII cyclones to dewater tailings ahead of filters. Overall, Xinhai’s hydrocyclones meet the diverse needs of modern ore beneficiation, from fine particle recovery to water reclamation.

Xinhai’s suite of mineral processing equipment – from grinding mills to thickeners, flotation cells, pumps and cyclones – embodies the company’s focus on innovation and turnkey service. Each machine integrates advanced features that improve performance and energy use. Backed by decades of experience and hundreds of full-scale projects, Xinhai delivers complete ore beneficiation equipment systems tailored to specific ore properties. Clients benefit from higher recoveries, lower operating costs, and a single-point supplier for engineering, manufacturing, and installation. Choosing Xinhai means accessing a proven, end-to-end solution for modern beneficiation – one that combines cutting-edge technology with the reliability of a well-established EPCM+O provider.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat