Environmental conditions such as climate, water availability, and terrain have a direct impact on the planning and construction of mineral processing and tailings projects. From high temperatures and freezing winters to heavy rainfall and drought, each challenge requires specific engineering solutions. At Xinhai, we integrate these factors into every project we deliver — ensuring safe, efficient, and sustainable results across diverse mining environments. The following sections explore how Xinhai tailors its strategies to address challenges related to climate, water resources, and topography.

1. Climate Considerations: Planning and Construction in Extreme Temperatures

In mineral processing and tailings engineering, extreme climate conditions — whether high heat or severe cold — pose significant challenges to project planning, construction, and long-term operation. Xinhai tailors solutions to address the unique obstacles presented by temperature extremes, ensuring safety, efficiency, and sustainability throughout the project lifecycle.

1.1 High-Temperature Regions

Typical Locations: Parts of Africa, the Middle East, Central Asia, Northern Australia, etc.

Equipment overheating: Machinery and electronic control systems may fail or underperform in extreme heat.

Process instability: High temperatures can affect flotation reagent performance, grinding efficiency, and leaching kinetics.

Worker health and safety: Long working hours under heat stress increase health risks and reduce productivity.

Concrete curing and material aging: Rapid moisture loss leads to cracks and reduced structural durability.

Enhanced cooling systems: Use water-cooled or air-conditioned enclosures for sensitive equipment and control rooms.

High-temperature-resistant materials: Select construction and lining materials with proven performance in +40°C environments.

Optimized reagent dosage: Adjust chemical formulations to maintain flotation and leaching performance.

Shaded and ventilated facilities: Design processing plants with passive cooling features and heat-reflective roofing.

Worker safety protocols: Schedule critical tasks in cooler hours (early morning/evening), provide cooling stations and hydration breaks.

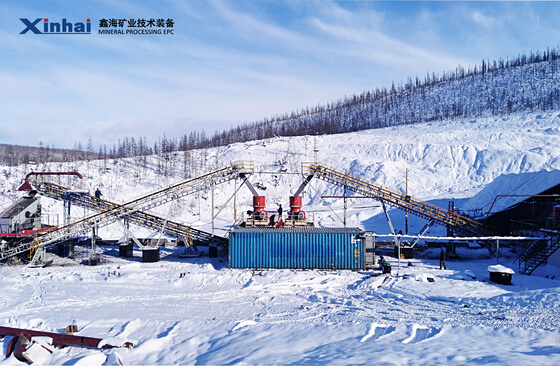

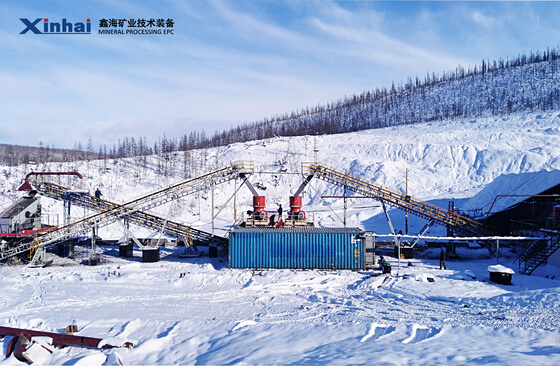

1.2 Cold and Permafrost Regions

Typical Locations: Russia, Canada, Mongolia, Northern China, and Arctic areas.

Frozen ground and permafrost: Excavation and foundation works become difficult and costly.

Water circulation issues: Pipes, pumps, and tailings discharge lines may freeze, halting operations.

Equipment startup problems: Lubricants and hydraulic fluids thicken, causing mechanical failures.

Concrete setting delays: Low temperatures prevent proper curing, reducing structural strength.

Winter construction limitations: Short daylight hours and harsh weather restrict working windows.

Thermal soil stabilization: Use insulated foundations or heating systems to prevent ground heaving and frost damage.

Antifreeze pipeline systems: Equip critical water and slurry lines with heating cables or insulation jackets.

Cold-weather lubricants and hydraulic fluids: Choose low-viscosity, winter-grade oils for heavy machinery.

Enclosed process facilities: Build heated enclosures for flotation, grinding, and filtration units.

Winter construction planning: Shift heavy civil works to warm seasons; use pre-assembled modular structures during cold months.

Preheating water and slurry: Maintain optimal process temperatures to avoid system shutdowns.

2. Water Resource Conditions: Planning and Construction in Rainy and Arid Regions

Water plays a critical role in mineral processing operations, from ore grinding and flotation to tailings transportation and storage. Both excessive rainfall and extreme water scarcity can severely disrupt project planning, construction, and operations. At Xinhai, we engineer site-specific water management strategies to optimize process efficiency and environmental protection under diverse hydrological conditions.

2.1 Rainy and High-Precipitation Regions

Typical Locations: Southeast Asia, Central and West Africa, South America (e.g., Amazon basin), South China.

Flood risks: Tailings ponds, open pits, and construction zones are prone to overflow or erosion during heavy rains.

Waterlogging: Saturated soils hinder excavation and equipment installation.

Tailings pond instability: Excessive surface runoff increases water volume in ponds, weakening dam safety.

Disrupted construction schedule: Prolonged rainfall reduces daily work hours and delays critical phases.

Environmental risk of polluted runoff: Surface water may carry heavy metals and process residues downstream.

Comprehensive drainage system: Install perimeter diversion ditches, stormwater channels, and sedimentation tanks to manage rainfall efficiently.

Tailings pond elevation and freeboard design: Maintain sufficient freeboard height; use emergency spillways for overflow control.

Rapid dewatering systems: Use pumps and mobile drainage units to clear flooded areas promptly.

Slope protection and erosion control: Apply geotextiles, rock armoring, and vegetation to prevent wash-outs on slopes and embankments.

Weather-adaptive scheduling: Plan major construction works during dry seasons; reserve buffer periods for weather-related delays.

Contaminated water containment: Build waterproof bunds and retention basins to isolate potentially harmful runoff from entering natural waterways.

2.2 Arid and Water-Scarce Regions

Typical Locations: Northern Africa, Central Asia, the Middle East, Northern Chile (Atacama Desert), parts of Western Australia.

Insufficient water for processing: Mineral beneficiation processes such as grinding, flotation, and thickening rely on large volumes of water.

Water evaporation losses: High temperatures and wind speeds accelerate water loss from tailings ponds.

Limited local water sources: Groundwater extraction may be unsustainable or regulated; surface water is often seasonal.

Community and environmental competition: Mining water use may create tension with local agriculture and ecosystems.

Water-efficient processing technology: Employ high-efficiency thickeners, filter presses, and closed-loop water circuits to maximize recycling.

Dry tailings discharge (dry stacking): Reduce or eliminate tailings ponds; stack filtered tailings directly for minimal water loss.

Desalination and alternative sources: For coastal regions, seawater desalination systems can provide a reliable supply.

Evaporation control measures: Use floating covers, windbreaks, or chemical evaporation suppressants on ponds and tanks.

Real-time water balance modeling: Monitor inflow, usage, and recycling rates continuously to optimize water usage.

Community engagement and transparency: Develop shared water management plans with local stakeholders to ensure sustainable operations.

3. Terrain and Topography: Challenges and Solutions in Mine Planning and Construction

Topography has a profound impact on the design, logistics, and safety of mineral processing and tailings engineering projects. Whether operating in mountainous highlands or flat basin regions, terrain-related conditions must be carefully assessed and addressed during the early planning and design phases. Xinhai provides terrain-adaptive engineering solutions to ensure stable, efficient, and environmentally responsible construction and operations.

3.1 Highland and Mountainous Regions

Typical Locations: Andes, Himalayas, Central Asia, Ethiopian Highlands, parts of Western China.

Steep slopes and unstable geology: Increased risk of landslides, rockfalls, and erosion.

Difficult transport and access: Haul roads and material logistics become complicated and expensive.

Limited flat land for plant construction: Site leveling and terracing are required for safe facility layout.

Altitude effects: Reduced oxygen levels can impact both workers and machinery performance.

Drainage management: Heavy rainfall or snowmelt can accelerate erosion and structural damage.

Geotechnical slope stabilization: Use retaining walls, rock bolts, shotcrete, and anchor systems to secure slopes.

Tiered facility layout: Design processing plants and tailings storage in a stepwise, elevation-based arrangement to utilize gravity and reduce pumping needs.

Customized road engineering: Design switchback or spiral haul roads with reinforced subgrades for reliable year-round access.

Oxygen-enriched work environments: For high-altitude sites, install oxygen stations and monitor worker health closely.

Surface water diversion and slope drainage: Create permanent channels and subsurface drains to reduce water pressure and prevent landslides.

3.2 Basin and Flatland Regions

Typical Locations: Central African basin, Russian plains, Northern China, parts of North America and Kazakhstan.

High groundwater levels: Excavation and foundation works may face seepage and instability.

Soft or compressible soils: Poor soil bearing capacity affects equipment foundations and dam construction.

Tailings pond seepage risk: Flat terrain may cause tailings water to spread and infiltrate surrounding land.

Dust generation: Dry flatlands often produce wind-blown dust during construction and dry tailings stacking.

Deep foundation and soil improvement: Use vibro-compaction, stone columns, or geotextile reinforcement to enhance ground stability.

Raised facility platforms: Build slightly elevated construction platforms to avoid water accumulation and ensure drainage.

Impermeable liners in tailings storage: Install HDPE or clay liners to prevent seepage into groundwater and surrounding areas.

Groundwater control systems: Use dewatering wells or cutoff walls to manage underground water intrusion.

Dust suppression measures: Apply water sprays, windbreak fences, and chemical suppressants to maintain air quality.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat