Throughout the mining industry's lifecycle, concentrators, as the primary link in resource monetization, directly determine a mine's economic benefits and resource utilization. However, with the continued advancement of mining operations and changes in the external environment, the adaptability challenges facing concentrators are becoming increasingly prominent, and expansion and renovation have shifted from being optional to mandatory.

From an industry perspective, the non-renewable nature of mineral resources dictates a natural upper limit to the service life of a mine. When the processes and equipment of existing mineral processing plants are mismatched with the ore body's mining stage, not only does this result in wasted resources, but it can also lead to premature decline of the mine. Furthermore, the global mining industry is transitioning towards a greener and more intelligent environment. Stricter environmental protection policies and rising energy costs are also forcing older mineral processing plants to upgrade their technologies to reduce operating costs and meet regulatory compliance requirements.

This article will introduce the difficulties in the renovation and expansion of the mineral dressing plant, the unique advantages of the renovation and expansion of the Xinhai mineral dressing plant, and related actual cases.

1. Difficulties in expanding and renovating a mineral processing plant

Compared to the flexibility of building a new processing plant from scratch, expansion and renovation projects require upgrading without or with minimal interruption to production, facing the complex challenge of balancing production, construction, and safety, making them far more difficult than new construction projects. This is mainly reflected in the following aspects:

Conflict between production and construction: Most mines cannot afford long-term shutdowns for renovations, so expansion and reconstruction must adopt a "partial shutdown, regional construction" model, which requires very high process connection, progress control and coordination capabilities.

Compatibility between old and new systems: Expansion and reconstruction is not simply a matter of adding new equipment or continuing the process. It is necessary to ensure that the old and new systems are compatible in terms of technical parameters and operating logic. Otherwise, problems such as the new equipment not fully operating and the old equipment lagging behind may easily arise.

Dual constraints of safety and environmental protection: During the expansion and reconstruction process, the construction area overlaps with the production area, and involves equipment dismantling, pipeline cutting, high-altitude operations and other links. The safety risks are significantly higher than those of new projects. At the same time, environmental protection indicators such as production wastewater and tailings must continue to meet standards and cannot be interrupted due to renovation.

Controllability of costs and construction periods: In expansion and renovation projects, hidden costs are prone to occur in links such as old factory structure renovation, underground pipeline detection, and equipment utilization evaluation. In addition, the construction period is affected by factors such as production plans and equipment delivery cycles, and the controllability is lower than that of new projects.

2. Xinhai Advantages of Mineral Processing Plant Expansion and Reconstruction

Leveraging the strong technical capabilities and extensive project experience of its Mine Design Institute, Xinhai Mining provides comprehensive solutions for mineral processing plant expansion and renovation to clients worldwide. We deeply understand the complexity and challenges of expansion and renovation projects, and based on this, we have built unique advantages in these projects.

1. Professional Design Capabilities

We hold Class B design qualifications in the metallurgical industry and employ over 100 design professionals across 18 disciplines, including mining, mineral processing, civil engineering, and automation. We have completed over 600 mining design projects, with processing capacities ranging from a few hundred tons to millions of tons per year and experience covering a wide range of complex terrains and conditions.

2. Scientific Design Process

During the design process, Xinhai prioritizes cost control and schedule optimization, effectively utilizing old equipment and reserving space for expansion to avoid hidden costs. To this end, the company conducts detailed on-site inspections and works closely with clients and their professional teams to ensure the scientific and practical nature of the proposed solution. While prioritizing cost control and schedule optimization, also we help clients reduce investment costs through rational selection and optimized design. Furthermore, it possesses independent intellectual property rights in tailings treatment and beneficiation process optimization, enabling it to provide clients with efficient and environmentally friendly solutions.

3. Diverse design options and international standards

We support the design of conventional, mobile, 3D, and modular steel structure mineral processing plants. Modular steel structure design reduces civil engineering workload, construction time, and investment, and facilitates disassembly and relocation.

Xinhai can design to Chinese standards, Australian JORC standards, Valmin specifications, and Canadian NI43-101 standards, making it suitable for both domestic and international projects.

4. Intelligent and Environmentally Friendly Empowerment

Integrating VR/AR and intelligent management and control systems into the design, we provide regulatory submission and drawing review services. Relying on proprietary intellectual property rights in tailings treatment and process optimization, Xinhai ensures the project meets environmental standards.

3. Xinhai Ore Processing Plant Expansion and Reconstruction Project Highlights

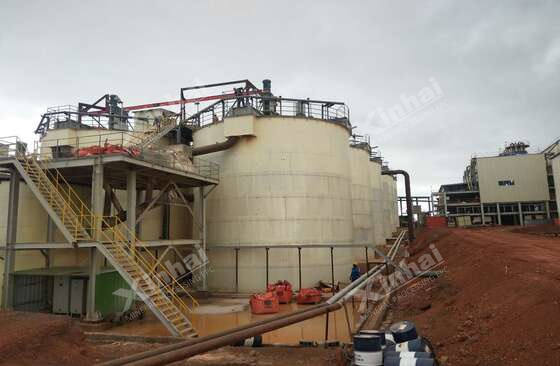

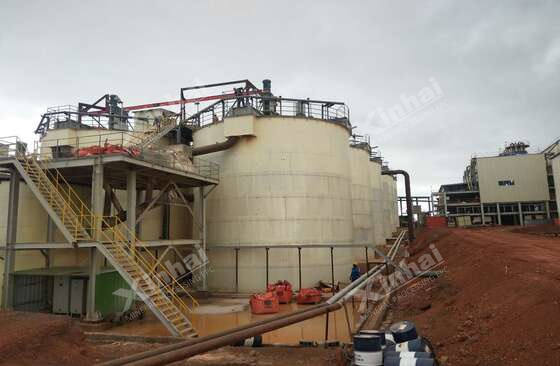

3.1 Guinea 6,000 t/d Gold Processing Plant Expansion Project

This project expanded from 4,000 t/d to 6,000 t/d. Xinhai provided full-cycle EPC services for the project, which was implemented in two phases.

Design Highlights:

Process Design: To address the clogging problem of powdered clay ore, Xinhai utilized a "gravity separation + cyanidation" process, strengthening the gravity separation and grinding processes and achieving a comprehensive gold recovery rate of 90%. Furthermore, a low-toxic, environmentally friendly leaching agent was used instead of sodium cyanide, reducing reagent consumption and costs while maintaining comparable performance indicators.Cost Control: Because concrete costs in Guinea were five times higher than in China, all above-ground structures utilized domestically prefabricated modular steel structures, assembled on-site. This reduces civil engineering costs and construction timelines while also ensuring aesthetics.

Flexibility in Equipment Procurement: Complete equipment technical specifications were provided, allowing customers to choose a combination of "Xinhai equipment + market procurement."

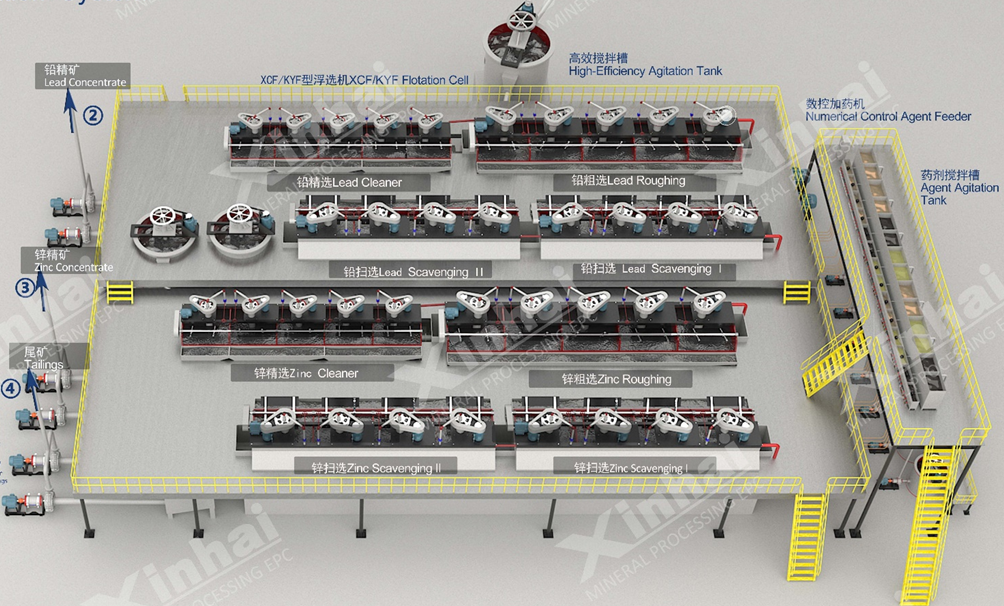

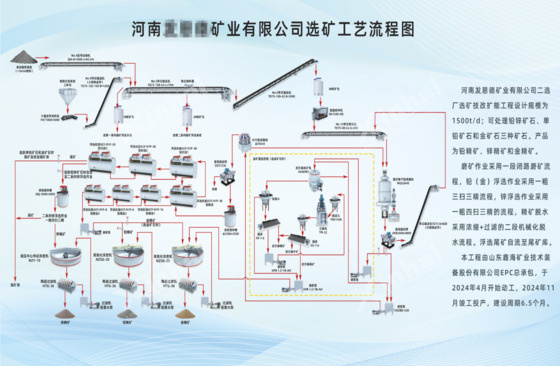

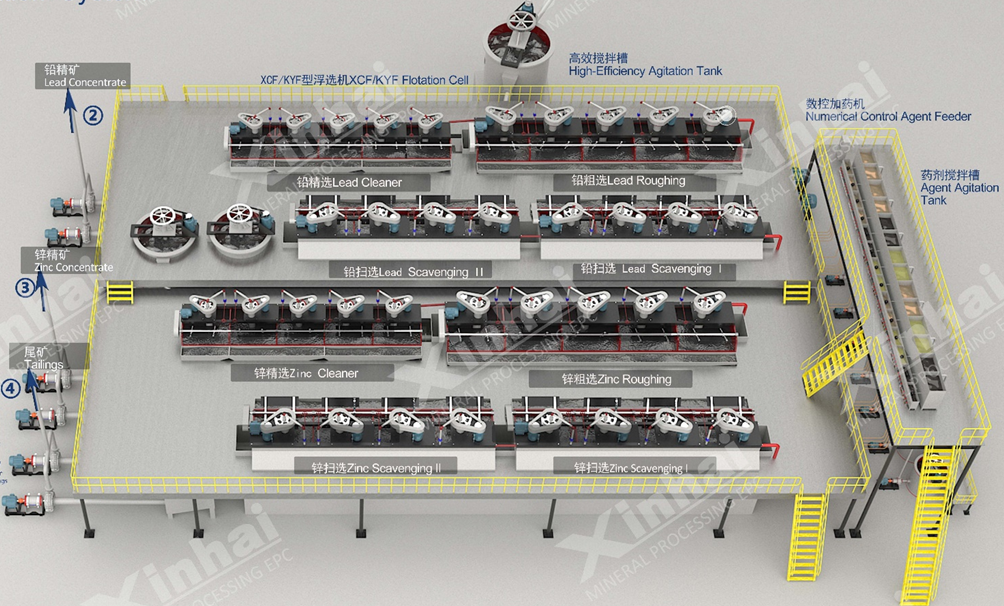

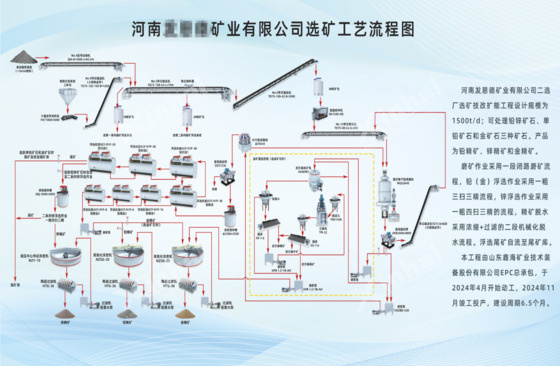

3.2 Henan 3,000 t/d Silver, Lead, Zinc, and Gold Polymetallic Ore Flotation Plant Expansion Project

The project aims to expand from 1,500 t/d to 3,000 t/d, with reserve capacity to reach 1,800 t/d. The client's primary goal is to double production capacity through this expansion and meet the needs of synergistic separation of silver, lead, zinc, and gold.

Design Highlights:

Strong Compatibility: The solution adheres to the principle of maintaining uninterrupted production throughout. The grinding, flotation, and concentration systems were all newly added rather than retrofitted. Only partial connections of belts and piping were required to ensure interoperability between the new and existing systems. During the expansion period, the existing 1,500 t/d production capacity can operate normally, avoiding production downtime caused by comprehensive renovations. Furthermore, the reserved 1,800 t/d of production capacity provided room for subsequent resource additions and capacity expansion, eliminating the need for a second, large-scale expansion.

Technical Compatibility: A risk in polymetallic ore separation is intermetallic inclusion. The solution mitigated this issue through three key design features: first, intelligent waste disposal for early impurity removal, reducing interfering minerals; second, Nelson gravity separation for early gold recovery, preventing competition between gold and lead and zinc minerals; and third, differentiated flotation stage design for precise control of reagent dosage and flotation conditions, ensuring the purity of lead and zinc concentrates and safeguarding the market value of the concentrates.

Excellent Economic Performance: Economic efficiency was fully considered in equipment selection and process design, utilizing a reuse and optimization approach. The two existing high-efficiency concentrators were reused to reduce investment in new equipment; they were optimized for intelligent waste disposal, effectively reducing the load on subsequent processes and reducing energy and chemical consumption; the serial expansion used a new plant building that was independent of the original one, eliminating the need for large-scale demolition and shortening the construction period.

3.3 Malaysia 300t/d Gold Mine CIL Expansion Project

The CIL concentrator expansion project at a 300tpd gold mine in Malaysia expanded its capacity from 500t/d to 800t/d. The project encompassed the entire process of "grinding and classification - leaching - filter pressing - water supply," aiming to improve grinding and leaching capacity, thereby enhancing the efficiency of the concentrator. Xinhai conducted targeted research and analysis on the concentrator and, based on the design philosophy of "system adaptation and optimization of existing systems," implemented an expansion and renovation design. This not only broke through the original production capacity bottleneck but also addressed operational issues with the old system.

Design Highlights:

Grinding and Classification System Upgrade + Equipment Reuse: A new grinding and classification process with two stages replaces the previous single classification process, creating a closed loop of "grinding-classification-return." Equipment reuse involves reusing the existing linear screen for chip removal in the new system. The existing linear screen was also replaced with a DZS1225, specifically addressing the pain points of the old system, including excessive debris and equipment clogging.

Leaching system capacity expansion: Based on the original 6 leaching agitator tanks, 4 new agitator tanks of the same model were added, and the total leaching capacity increased by 67%, directly matching the 800t/d slurry processing demand. In addition, a new high-pressure Roots blower was added to solve the problem of insufficient air supply in the original system's No. 5 and No. 6 agitator tanks, while meeting the carbon cross-linking demand of the newly added tanks. The original safety screen was replaced with a DZS1225 to improve screening efficiency. Some DN150 pipelines were uniformly replaced with DN200 welded steel pipes to solve the bottleneck of slurry transportation. In view of the insufficient slurry height difference caused by the newly added tanks, a slurry pump was added to pump the slurry to the original leaching adsorption tank to ensure smooth slurry flow.

Filter Press System Equipment Addition + Process Adaptation: A new chamber filter press, equipped with a feed pump and bottom belt conveyor, increased tailings filtration capacity by 30%. The feed pump was connected to the bottom of the renovated tailings buffer tank to ensure a stable slurry supply. Return water flows by gravity to the existing filtrate tank, achieving water recycling. The existing transfer belt was lengthened to accommodate the tailings transfer needs of four filter presses.

Water Supply System Reuse + Local Adaptation: No new water supply pumps were added, directly utilizing the existing elevated water tank for water supply, reducing equipment investment and energy consumption. Furthermore, the new water supply pipeline utilizes PE pipe, taking into account the abundant local supply of PE pipe fittings in Malaysia, reducing pipeline procurement and maintenance costs.

Xinhai's renovation plan was not a simple step-by-step approach. Instead, it addressed capacity bottlenecks through process upgrades, reduced costs through the reuse of existing equipment, and eliminated pain points through targeted renovations, ultimately achieving a dual improvement in efficiency and profitability throughout the entire process. Leveraging its strengths of "professional design capabilities, scientific process control, diverse technology options, and intelligent environmental protection," Xinhai Mining provides a replicable "Xinhai Solution" for the expansion and renovation of mineral processing plants worldwide. In the future, as the demand for greener and more intelligent mining deepens, Xinhai will continue to prioritize technological innovation, helping more mines maximize resource value through scientific expansion and renovation, and driving mining development towards efficiency, low carbon, and sustainability.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat