Xinhai’s K-series large circular flotation machines combine advanced tank geometry, robust manufacturing and intelligent control to lift recovery, reduce energy use and simplify site maintenance — proven on large copper projects such as a 3.5 Mt/a Zambia plant.

In large copper and polymetallic plants, flotation remains the single most critical step for separating target minerals from gangue. As processing capacity and ore complexity rise, flotation equipment must deliver three things simultaneously: high recovery, stable operation, and low total cost of ownership. Xinhai’s K-series large circular flotation machines (KYF-type large circular cells) were developed specifically to answer these demands — rethinking cell geometry, drive options, manufacture and online control to make flotation more predictable at scale.

1. Equipment R&D & design governance

A repeatable, auditable R&D process is the backbone of reliable equipment. For the K-series Xinhai emphasizes:

Single-source data and collaborative CAD environment: design data consistency across engineering, procurement and manufacturing avoids mismatches that lead to rework and delays.

Standardized enterprise design standards in SW (CAD/PLM) environments: consistent templates, parts libraries and version control reduce human error during model changes.

SOP-driven workflows and traceability: design decisions, approvals and manufacturing records are logged so any deviation can be traced and resolved.

These practices shorten development cycles and provide mine owners with verifiable quality records — particularly important for large EPC and turnkey contracts where equipment must integrate seamlessly with plant process design.

2. Innovative solutions — dual drive philosophy (Asynchronous vs. Permanent-Magnet)

Xinhai offers two drive options for its large circular flotation machines: the conventional three-phase asynchronous (induction) motor and a permanent-magnet synchronous motor (PMSM) option. Both have their place; the choice depends on site priorities (CAPEX vs OPEX, local spares & service capability, operational profile).

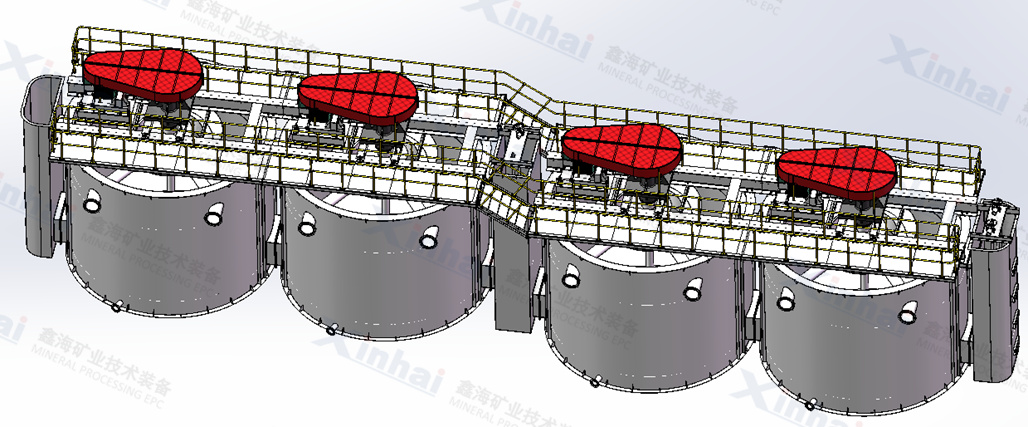

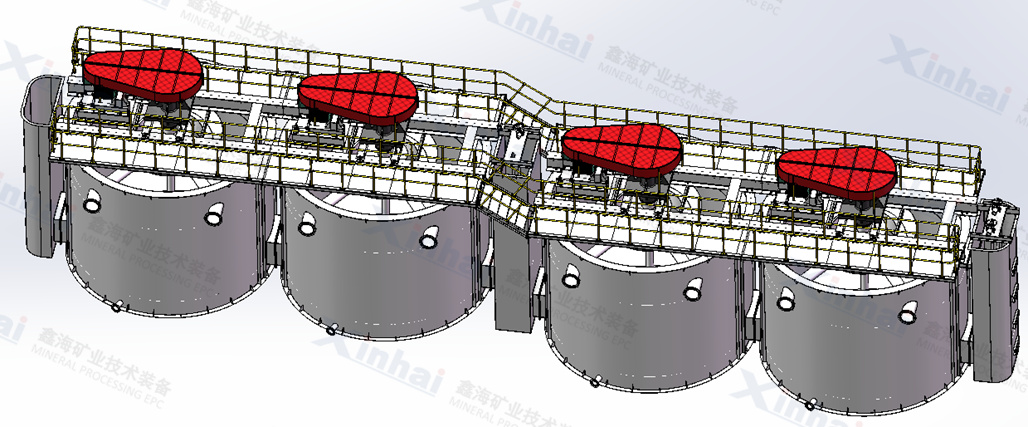

circular flotation machines with ordinary three phase asynchronous motor drive

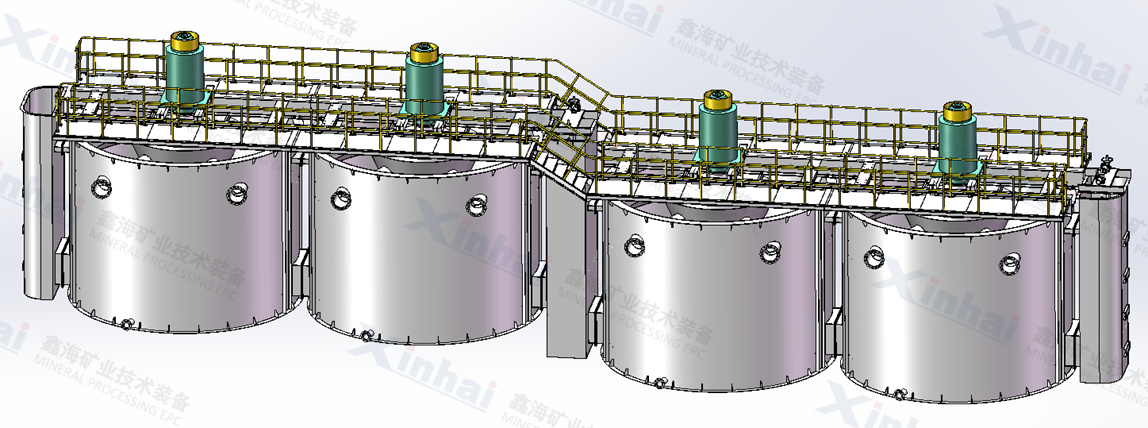

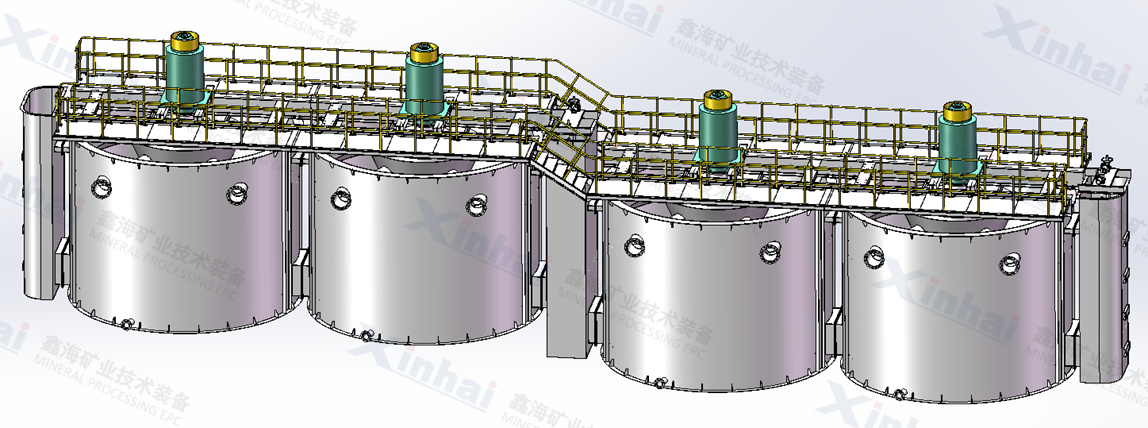

circular flotation machines with permanent magnet synchronous motor drive

Operational advantages of PMSM in flotation include:

* Higher motor efficiency — less electrical loss and reduced thermal loading on bearings and seals.

* Lower overall energy consumption — real installations and studies report meaningful savings, often in the single- to double-digit percent range.

* Finer speed and torque control — benefits flotation control when operators adjust impeller speed for different circuits/stages.

* Smaller footprint and lighter weight — eases layout and handling for large-scale plants.

* Simplified electric control & maintenance — predictive maintenance and reduced operator skill barriers.

Xinhai thus provides both a proven induction option (lower initial cost and broad serviceability) and a PMSM option (lower life-cycle energy and better control) so customers can select according to their CAPEX/OPEX balance.

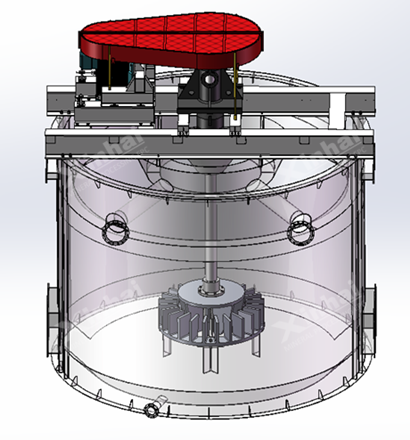

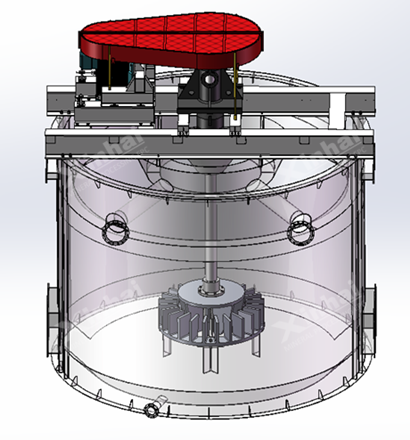

3. K-Series structural and hydraulic innovations — design that improves flotation fundamentals

The K-series large circular flotation cell combines several engineered features that target hydrodynamics, froth handling and durability:

* Circular tank with conical bottom: promotes even air dispersion, stabilizes slurry surface and prevents sand/silt pooling.

* Dual circular froth launders + froth cone per cell: shortens froth transport distance and reduces local froth stagnation.

* Uniform stress distribution from circular geometry: reduced material requirements and lower weight without compromising strength.

* Thick-wall main shaft with 5 mm rubber sleeve at slurry interface: acid-, oil- and wear-resistant protection that extends MTBF.

* Dual-cone liquid valves with pneumatic regulation for mid/tail boxes: tight and reliable level control for steady flotation conditions.

* Backward-curved high-specific-speed impeller + low-damping straight-suspension stator: large flow with low head and reduced circulation resistance.

* Taper-bush pulleys & bolt-connected tank modules: easier onsite maintenance, faster assembly, fewer welds in the field and a greener installation process.

* Full-closure safety guards and ergonomically designed access: addresses site HSE requirements and reduces exposure during maintenance.

These structural choices lift flotation stability and concentrate grade while lowering total installed weight and simplifying site work.

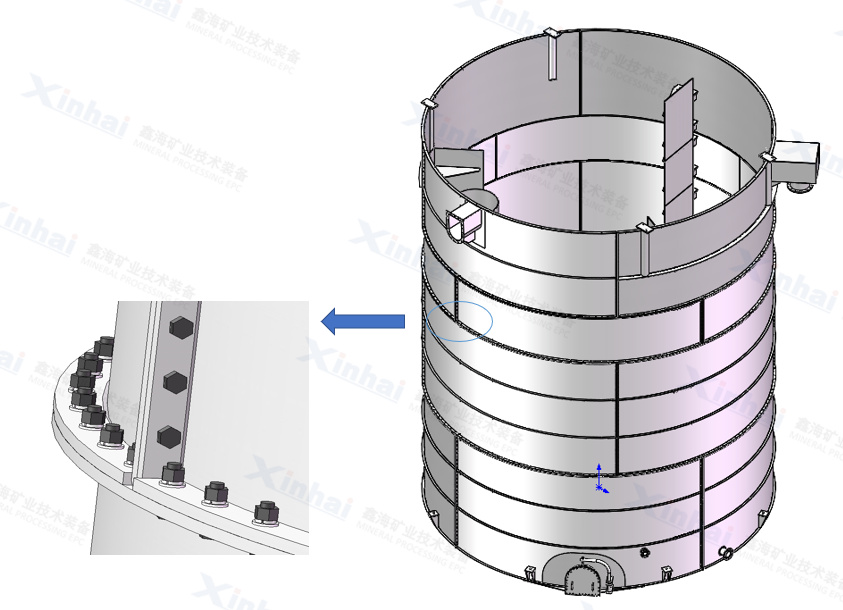

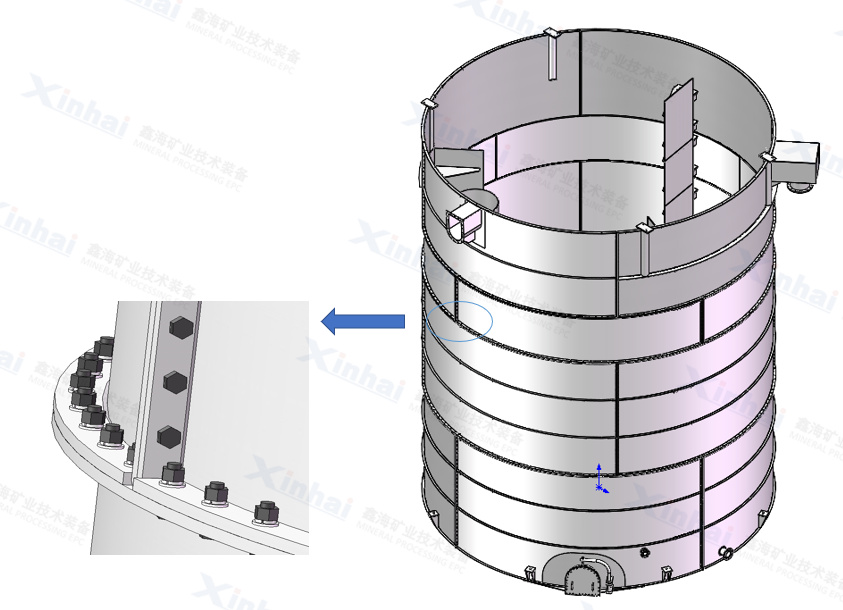

4. Manufacturing precision & factory-first installation model

Quality manufacturing underpins field performance. Xinhai’s K-series is produced with advanced factory processes to reduce field variability:

* Fully automatic CNC laser cutting: tight, clean cuts with minimal plate deformation; tank-to-box gaps kept ≤ 3 mm.

* Automated welding platforms & infrared calibration: after welding, the overflow weir parallelism is controlled within ±5 mm per meter.

* Bolt-together tank assembly: moves most welding into the controlled factory environment, reducing site welding and shortening installation cycles.

These controlled processes reduce field variability and improve reproducibility of flotation performance.

large tank connected with bolts

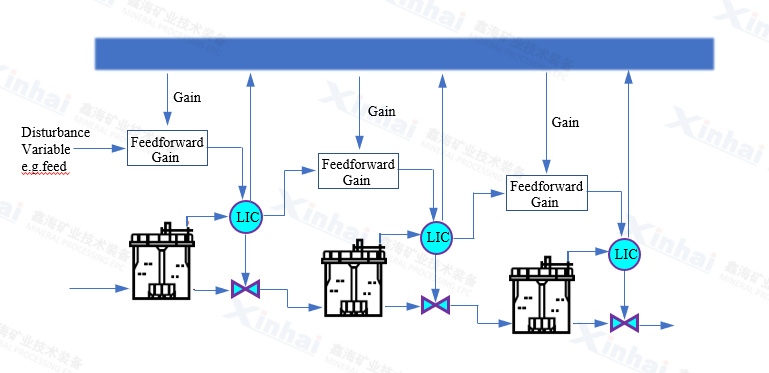

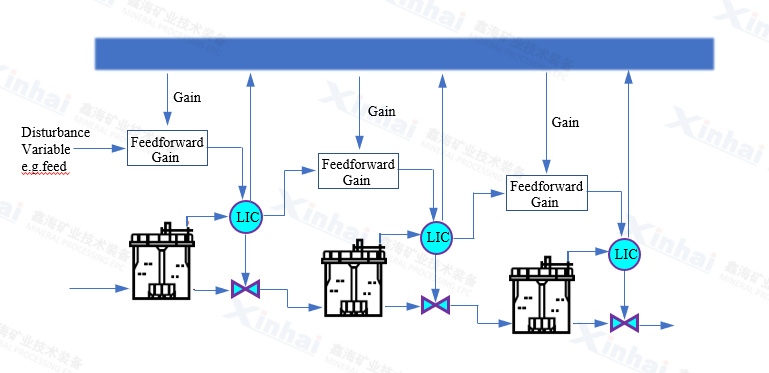

5. Intelligent automation — turning data into stable flotation

The K-series is a platform for automation:

* Slurry level & aeration control (PLC + pneumatic actuators): feedforward and closed-loop strategies keep bank levels stable.

* Froth image analyzer (computer vision): monitors froth speed, color, texture and overflow for actionable data.

* Online slurry grade analyzer (XRF): real-time elemental readings for rapid control decisions.

* High-precision intelligent reagent feeder: delivers reagents with high control resolution.

* Integrated flotation optimization control system: links analyzers, froth imaging, level control and dosing into DCS/SCADA logic for auto-tuned setpoints.

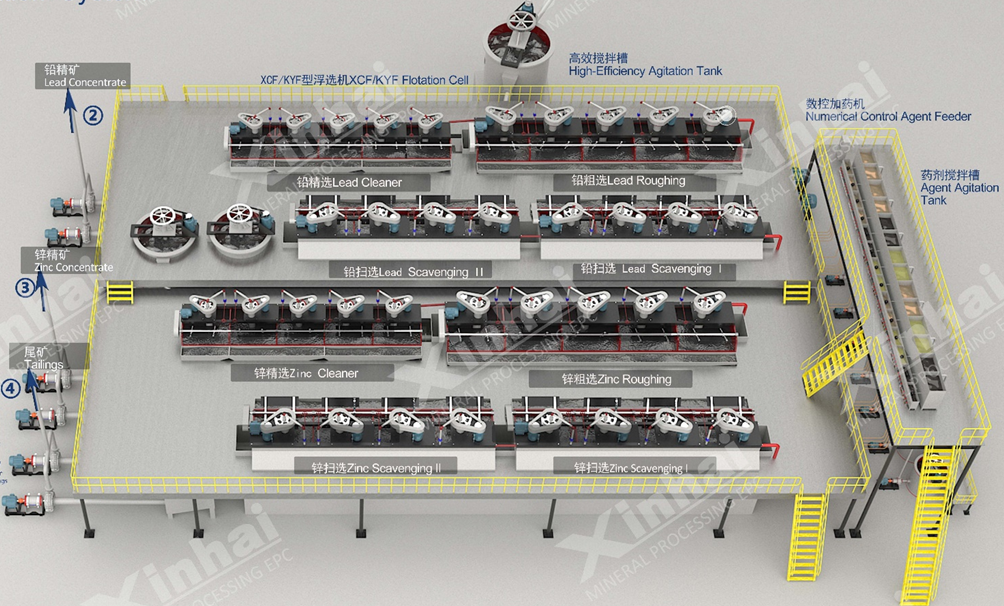

6. Project applications — real plants, measurable gains

Xinhai’s K-series has already been deployed on large projects:

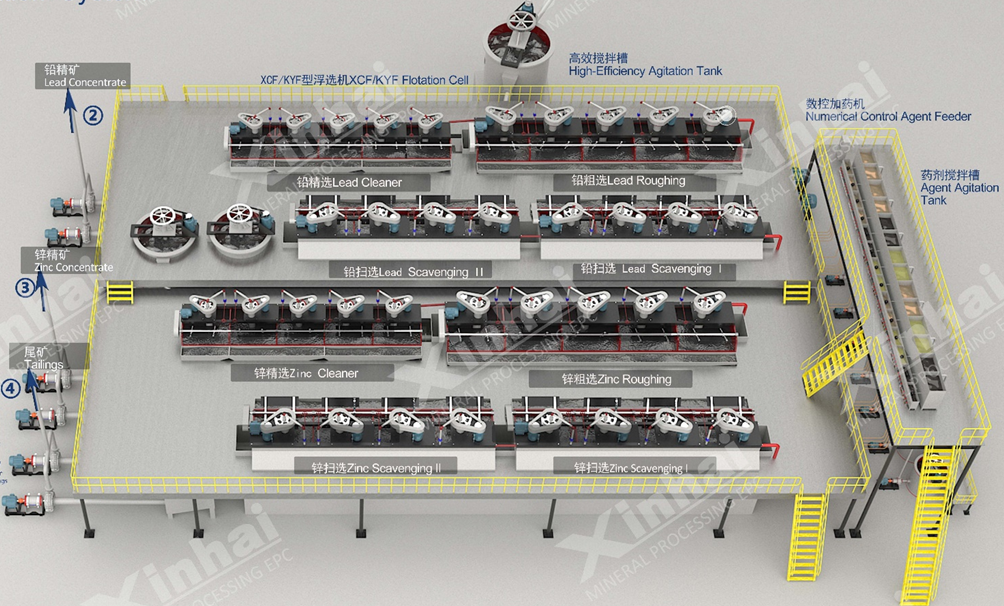

* Zambia — 3.5 Mt/a copper concentrator (recent project): Xinhai supplied a package including 17 KYFⅡ-130 large circular flotation machines along with supporting XCF/KYF cells, high-efficiency agitators and an automated control system.

* Kazakhstan — K100 units in design/engineering phase for a copper project.

For new projects, MiningTurnkey can provide technical summaries and equipment spec sheets referencing the Zambia case and the K-series performance metrics for tender submissions or client presentations.

7. How K-series fits an EPC / Turnkey scope

For mining owners seeking an EPC or EPC+M+O partner, the K-series is designed to integrate cleanly:

* Factory-fit modular tanks that bolt together on site shorten installation windows.

* Motor options let owners choose lower CAPEX with induction or lower life-cycle cost with PMSM.

* Built-in automation reduces commissioning tuning time and supports remote/centralized process control within a DCS scope.

These attributes make the K-series a sensible fit for modern, large-scale flotation banks where uptime and predictable recovery are economic drivers.

8. Equipment Model Selection

Model Type | Tank Diameter

(mm) | Tank Height

(mm) | Effective Volume

(m³) | Processing Capacity

(m³/min) | Blower Air Pressure

(kPa) | Maximum Inflation Volume

(m³/㎡*min) | Spindle Motor Power

(kw) |

KYF-70 | 5200 | 4200 | 70 | 20-50 | ≥45 | 1.5 | 110 |

KYF-100 | 5800 | 4560 | 100 | 20-60 | ≥52 | 1.5 | 185 |

KYF-130 | 6200 | 4800 | 130 | 20-60 | ≥55 | 1.5 | 220 |

KYF-160 | 6800 | 5500 | 160 | 20-60 | ≥60 | 1.5 | 250 |

KYF-200 | 7500 | 5600 | 200 | 20-100 | ≥65 | 1.5 | 280 |

KYF-320 | 8600 | 6500 | 320 | 20-150 | ≥73 | 1.5 | 315 |

Xinhai’s K-series large circular flotation machines represent a synthesis of structural hydraulics, precision manufacturing and embedded digital control — all aimed at delivering stable flotation performance at industrial scale. Proven installations such as the Zambia 3.5 Mt/a project demonstrate the design intent in actual operation. If you manage a flotation circuit or are preparing tender documents for a processing turnkey can help adapt the K-series specification to your process, match impeller sizes, drive selection, automation modules and spare parts lists, and produce detailed equipment. datasheets or EPC proposals.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat