Introduction

In the heart of Xinjiang, China, a remarkable gold mining endeavor is taking shape, showcasing the unparalleled capabilities of Xinhai Mining Technology & Equipment Inc. The Bogutu Gold Mine Expansion Project in Teks County, Xinjiang, with its impressive annual processing capacity of 2 million tons, stands as a powerful testament to Xinhai’s expertise in designing, supplying, and installing cutting-edge mineral processing infrastructure. This ambitious project not only highlights Xinhai’s technical prowess but also marks a significant milestone in establishing the company as a leader in large-scale mining solutions in the region.

Project Overview

Located in Xinjiang’s Teks County, the Bogutu Gold Mine originally operated with a single processing line handling 2000 tons per day (tpd). Seeking to capitalize on the region’s rich gold deposits, the client partnered with Xinhai to expand the facility by adding a second processing line with a capacity of 4000 tpd. This expansion triples the mine’s total throughput to 2 million tons per annum (tpa), positioning it as a benchmark project in North Xinjiang. While the existing crushing and testing systems remain under the client’s purview, Xinhai took charge of the design, equipment supply, and installation—from the grinding system through to the concentrate dewatering system—delivering a comprehensive upgrade to the mine’s processing capabilities.

Design

This construction drawing design project covers the technical renovation of a mineral processing plant, primarily involving the construction of a new fine ore silo, a grinding system, a flotation system, and the renovation of the concentrate dewatering system. The raw material for the mineral processing plant is gold ore, which enters this system after being processed by the crushing and screening system. This technical renovation project design adds a conveyor belt from the crushing system to feed a new fine ore silo, which then feeds the ore from the silo to the newly added grinding system. Two new grinding trains will be constructed, employing a closed-circuit grinding process with one stage of grinding and two stages of classification. The slurry after grinding and classification flows by gravity into the flotation system. The flotation system utilizes a single train process with one coarse, three scavenging, and four fine finishing. The coarse and scavenging flotation cell will be newly constructed, while the fine finishing flotation cell will be renovated from existing equipment. The gold concentrate dewatering process utilizes a two-stage mechanized dewatering process of thickening and filter pressing. The concentrate thickening process utilizes the existing thickener, while the concentrate dewatering process utilizes an additional filter press in addition to the existing filter press. The overflow from the thickener will be recycled back into the recirculation system. The flotation tailings will be fed by gravity into the tailings pond through the existing system.

Equipment

The Bogutu Gold Mine Expansion Project features a meticulously engineered design aimed at enhancing efficiency and output. Key components of this technical renovation include:

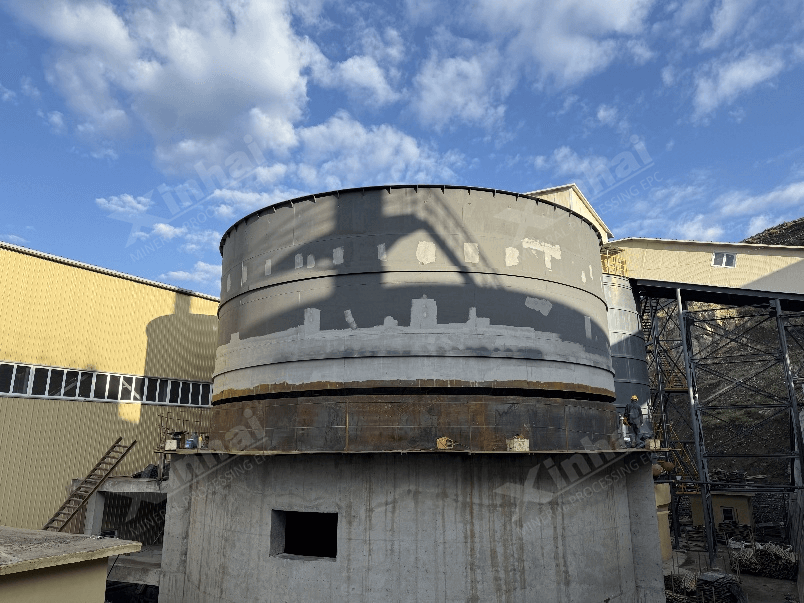

New Fine Ore Bin: A newly constructed bin receives crushed ore from the existing crushing system via an additional conveyor belt, ensuring seamless integration with the expanded workflow.

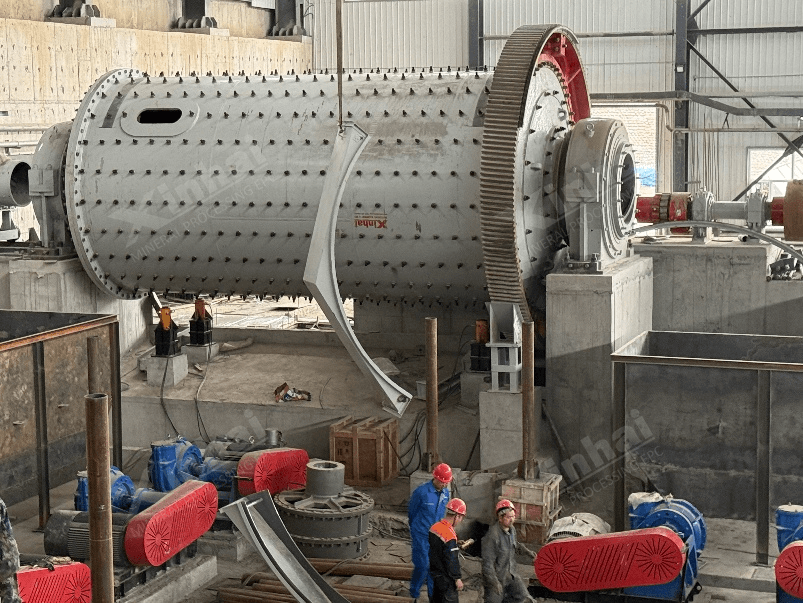

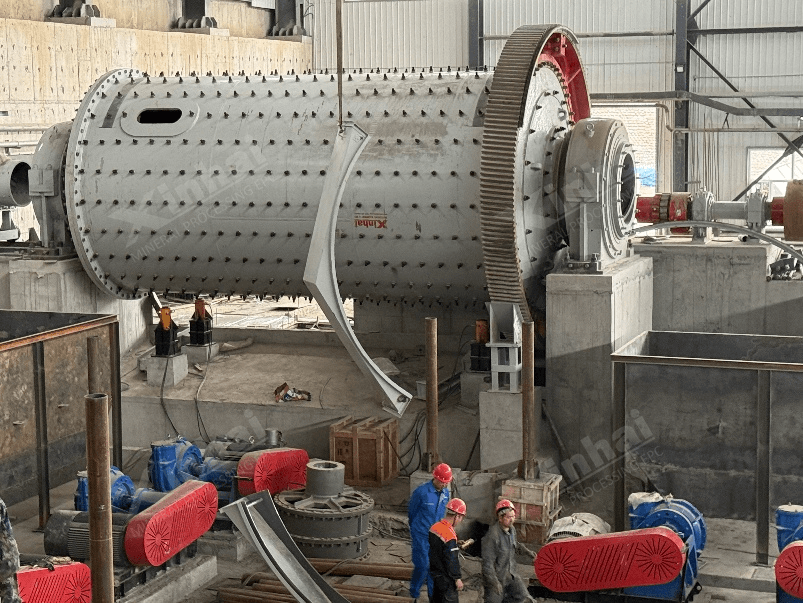

Advanced Grinding System: Two series of one-stage grinding and two-stage classification form a closed-circuit process, powered by two MQYg3672 overflow ball mills. These large-scale mills, equipped with high-efficiency motors and robust bearing systems, are designed to handle the increased ore volume with precision and reliability.

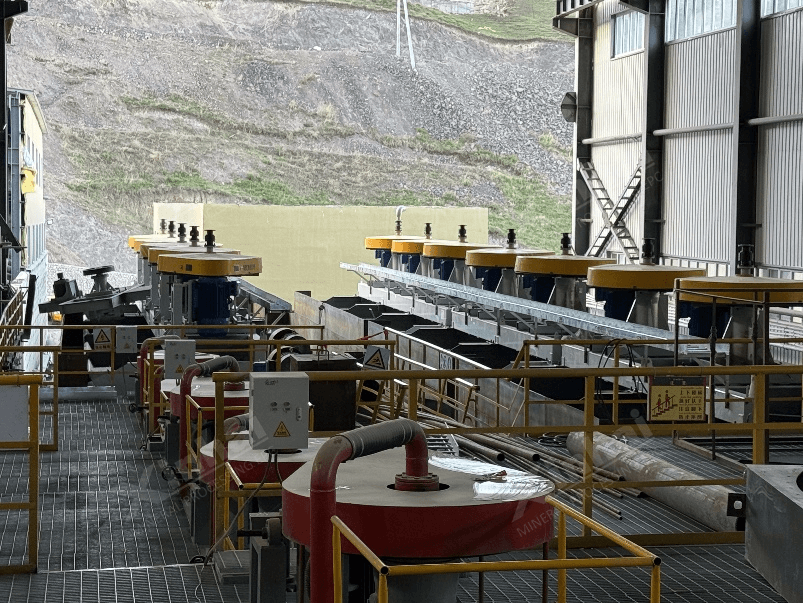

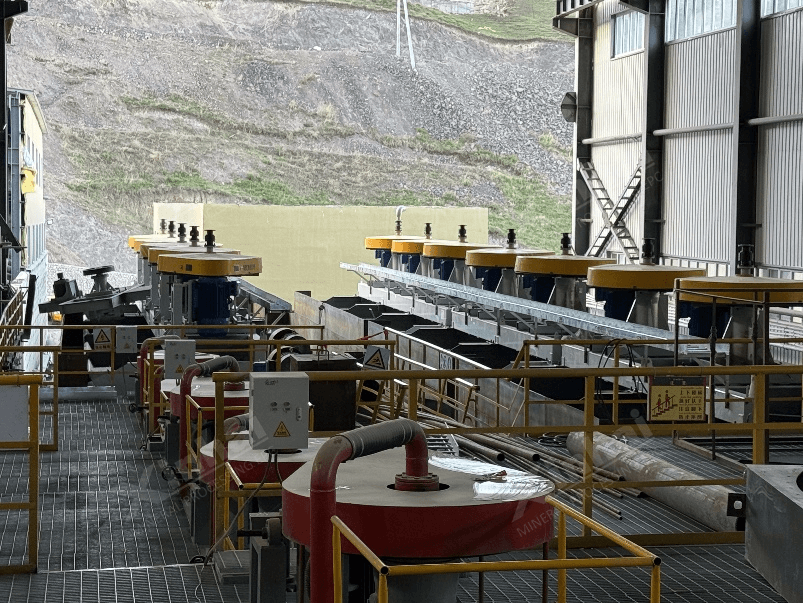

Robust Flotation System: Comprising twelve 50m³ flotation machines, the system follows a one-roughing, three-scavenging, and four-cleaning process to maximize gold recovery. A standout feature is the use of fiberglass-reinforced plastic (FRP) belt covers, replacing traditional steel covers. These FRP covers offer enhanced stability, reduced weight, lower maintenance costs, and improved durability—demonstrating Xinhai’s innovative approach to equipment design.

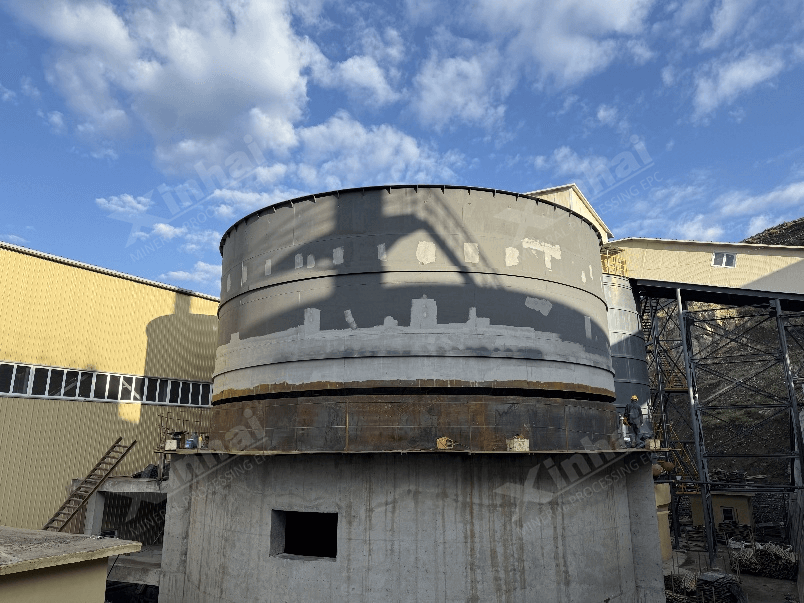

Enhanced Dewatering System: The concentrate dewatering process employs a two-stage mechanical approach. An existing thickener was modified by Xinhai—raised by 1.5 meters to a diameter of 18 meters—to increase capacity for both processing lines. A new hydraulic chamber filter press was also added to complement the existing press, ensuring efficient moisture removal.

Supporting these core systems are ancillary equipment such as belt feeders, conveyors, linear screens, cyclone groups, mixing tanks (φ4.5m x 4.5m), and slurry pumps, all tailored to optimize the gold processing workflow.

Installation Challenges and Solutions

The installation phase, executed under a “labor-only” contract, saw Xinhai provide a skilled workforce of approximately 70 technicians, while the client supplied materials and machinery like cranes. Concrete foundations supported the equipment, with steel platforms topped with galvanized grating used for the ball mills, flotation machines, and reagent areas. At its peak, five work zones operated simultaneously.

The installation phase of the Bogutu Gold Mine Expansion Project presented a unique set of challenges that underscored the complexity of large-scale mining operations. Despite the intricate nature of the project, which involved coordinating multiple work zones and assembling equipment shipped in parts, Xinhai’s team demonstrated exceptional adaptability and technical expertise. The installation of large-scale machinery, such as the MQYg3672 ball mills and 50m³ flotation machines, required meticulous precision and a deep understanding of engineering principles. Xinhai’s technicians rose to the occasion, ensuring that each component was aligned and assembled with the utmost accuracy, even under demanding conditions. This commitment to excellence in the face of logistical and technical hurdles highlights Xinhai’s capability to deliver high-quality results in complex environments. For instance:

Ball Mill Precision: Aligning the MQYg3672 ball mills’ transmission and cylinder required exacting adjustments using shim plates and laser alignment tools to ensure parallelism, safeguarding operational efficiency.

Flotation Cell Alignment: The 50m³ flotation machines demanded precise leveling and flatness to maintain slurry flow and flotation kinetics, a task Xinhai’s technicians mastered despite challenging conditions.

These efforts underscore Xinhai’s ability to deliver high-quality installations under complex circumstances.

Xinhai’s Strengths

Xinhai’s role in the Bogutu Gold Mine Expansion Project highlights several core strengths:

Large-Scale Project Expertise: With a 2 million tpa capacity, this project is a standout in Xinjiang, drawing attention from government officials and industry peers as a regional benchmark. Xinhai’s seamless execution reinforces its capability to manage substantial mining ventures.

Cutting-Edge Equipment: The deployment of MQYg3672 ball mills, 50m³ flotation machines, and an 18m-diameter thickener showcases Xinhai’s proficiency in supplying and integrating high-capacity machinery tailored to client needs.

Innovative Solutions: The use of FRP belt covers exemplifies Xinhai’s forward-thinking approach, enhancing equipment performance while reducing operational costs—a clear competitive edge.

Precision Installation: Overcoming logistical hurdles, Xinhai’s meticulous installation of large equipment—ensuring flatness, alignment, and parallelism—demonstrates unmatched technical skill and dedication to quality.

Xinhai remains committed to the project’s success, planning to deploy a team—including Installation Manager Jiang Mingxi and commissioning specialists—by August 2025 to address these challenges and finalize plant commissioning.

The Bogutu Gold Mine Expansion Project exemplifies Xinhai Mining Technology & Equipment Inc.’s ability to deliver world-class mining solutions. From innovative design and advanced equipment to expert installation, Xinhai has proven its mettle in tackling large-scale projects with precision and resilience. As this high-profile initiative nears full operation, it solidifies Xinhai’s reputation as a trusted partner in the global mining industry.

Xinhai has demonstrated its ability to drive industry innovation through its exceptional performance in major mining projects, including the Bogutu Gold Mine expansion. This project exemplifies how Xinhai's expertise and innovative solutions can help mining companies achieve their operational goals and set a new benchmark for the industry.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat