As the mining industry accelerates its digital transformation, Xinhai Mining delivers cutting-edge mining automation solutions that integrate smart sensors, PLC/DCS control systems, and cloud-based platforms into one intelligent ecosystem. Through its advanced Xinhai Automation Systems, the company enables real-time process optimization across crushing, grinding, flotation, dewatering, and tailings backfill. With centralized control, closed-loop adjustments, and remote monitoring, Xinhai helps mining plants operate safely, efficiently, and around the clock with minimal human intervention. Next, we will introduce you to the core equipment system, practical application cases and unique advantages of Xinhai Mine Automation.

Core Automated Systems

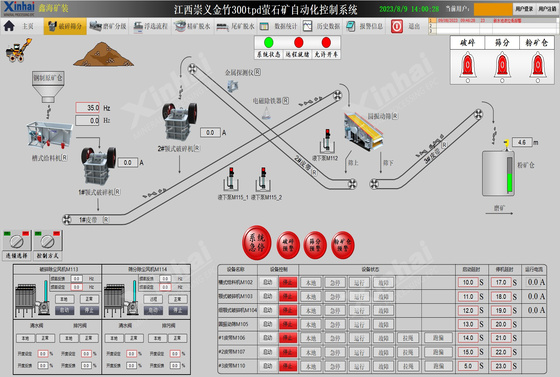

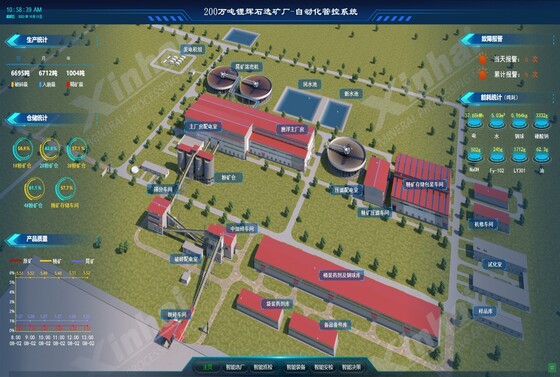

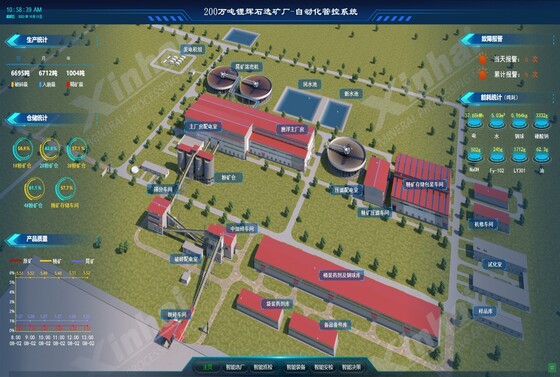

Mineral Processing Automation System

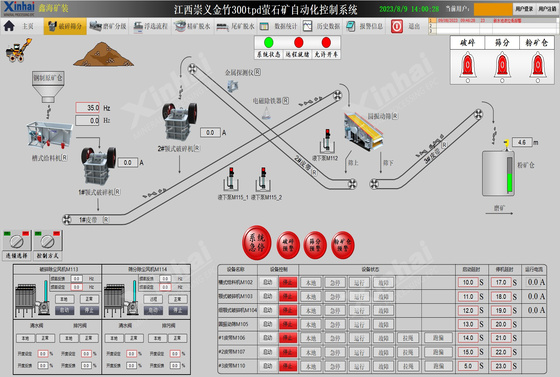

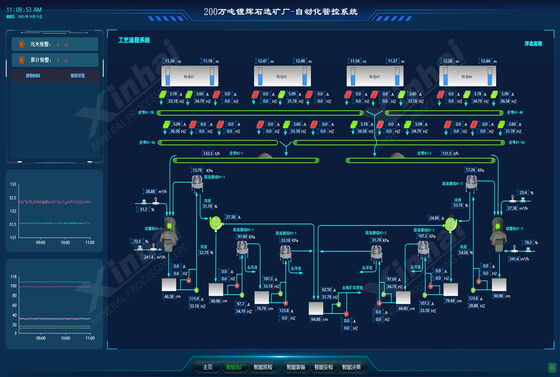

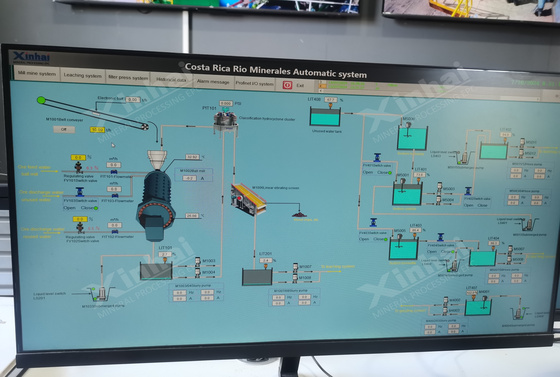

Xinhai’s flagship solution is a “whole-process” automation system for mineral processing plants. This system covers every stage from ore reception and crushing through grinding, classification, flotation and concentrate dewatering. It relies on comprehensive instrumentation and control logic to keep each unit operating at peak performance. For instance, the system continuously adjusts feed rates and water addition in grinding circuits to maintain target pulp density, preventing “over- or under-filling” of mills and cyclones. Similarly, flotation cells are equipped with automated level control valves and air-flow regulators so that slurry level and bubble aeration remain constant, even as ore characteristics vary. All major equipment has electrical interlocks and protection: crushers and conveyors are chained in sequence (one-key start/stop), and high-level sensors trigger alarms or automatic shutdowns to prevent overflows. By linking these functions, Xinhai’s mineral-processing automation stabilizes the entire plant flow, improves metallurgical recovery, and frees operators from manual tuning. The system also incorporates full-scope monitoring – for example, mill vibration and lubrication are tracked by sensors – so maintenance can be predictive rather than reactive. In short, Xinhai’s end-to-end automation ensures that crushing, grinding, flotation and tailings discharge work in harmony, maximizing throughput and consistent product quality.

Automated Filling System

Tailings or underground backfill is another area where Xinhai provides specialized automation. The Automation System of Filling handles preparation and delivery of filling material (e.g. cemented tailings) into mine voids. As described on Xinhai’s product site, this system controls slurry preparation, pumping and distribution using automated pumps, slurry mixers and valves. Key functions include automatic pulp (slurry) concentration control, dosing of binder, flow regulation into pipelines, and agitating-tank level control. In practice, the system can maintain a stable fill concentration at the set point: if sensors detect a drop in pulp density, the controller will adjust water or cement feed to compensate. One benefit is reduced manual labor: operators no longer need to climb next to hose outlets to sample slurry; instead an automated sampler and sensors provide continuous feedback. According to Xinhai, automated filling “stabilizes the filling concentration, improves the filling effect and reduces labor intensity”. In a recent project, Xinhai deployed this filling automation in a 1,500 t/d polymetallic plant in Henan, China, achieving uniform backfill quality and safer operations.

Control & Monitoring Platforms

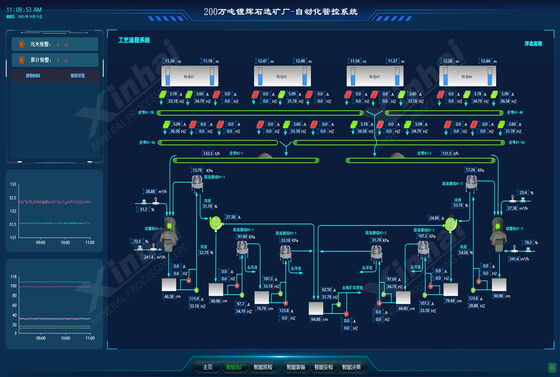

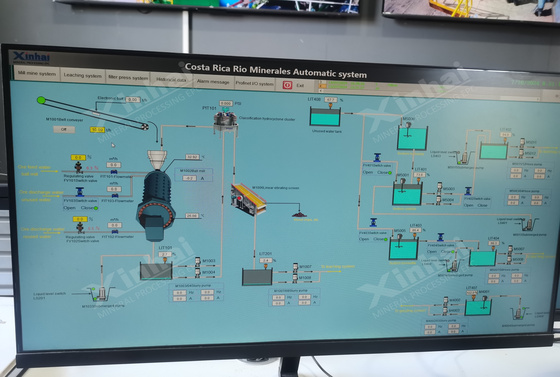

Xinhai’s smart solutions include advanced supervisory technologies. Their XHIMC intelligent control cloud platform acts as the brain of the operation, providing data aggregation and analysis. Through this web-based platform, all plant data – from flow rates to power consumption – are stored in the cloud. Managers can view interactive charts (e.g. energy usage, production reports, shift logs) that would otherwise be hidden behind isolated systems. The platform uses cloud computing and mobile terminals for remote access, so engineers and executives anywhere can “log in” to monitor equipment health and process KPIs. In parallel, Xinhai often deploys dedicated video surveillance and large-screen display systems in the control room: HD cameras cover all key areas, and big-display consoles can switch between process schematics and live video feed. This means a single control room operator can supervise the whole plant visually and data-wise. Xinhai’s approach even extends to on-equipment automation: for example, belt feeders, dosing machines and even lubricant dispensers can be automated and integrated into the SCADA system. In practice, whether monitoring a sensor or overhauling a control loop, all information streams back to the control center or cloud portal.

Applications and Showing Cases

Xinhai’s automation systems have been applied in numerous global mining projects under its EPCM+O framework. These real-world cases illustrate the effectiveness of Xinhai’s solutions:

Zimbabwe Bikita 2 MTPA Lithium Project: Xinhai engineered a turnkey plant for spodumene processing, with a fully integrated intelligent plant solution. The system covers crushing, grinding, floating and dewatering, all under a unified control strategy. Customized automation equipment was provided for crushers, ball mills, cyclones, flotation machines, automatic lubrication units, chemical dosing and ball charging machines, and automated samplers. For example, Xinhai’s crushers include real-time monitoring of load, motor current and chamber levels; the control system can adjust drive frequency or stop the crusher automatically based on feed level. Flotation banks are fitted with automatic level controllers that respond instantly to slurry volume changes. Overall, the automation enabled 24/7 unmanned operation: the control room manages start/stop sequences, interlocks and process setpoints for the entire plant, improving recovery and reducing costs.

Fiji Gold Plant (2,000 t/d): Xinhai supplied an automated gold concentrator in Fiji, as part of a 2,000 t/d gold tailings and ore project. The plant uses a centralized control room where operators can oversee all process parameters. The automation covers every segment – from coarse crushing to gravity and flotation – and even automates routine inspections. According to Xinhai, this project’s control room is staffed by only 2 operators per shift (with three shifts per day). All equipment alarms, trending curves and production parameters are monitored centrally, making site operation largely unmanned. This setup improved the gold recovery stability and allowed remote troubleshooting, while periodic field patrols by automated drones or inspection teams maintain equipment.

Pakistan Copper Plant (1,500 t/d): In a 1,500 t/d copper concentrator project in Pakistan, Xinhai installed twin PLC-based control systems. One PLC manages the crushing circuit and the other controls the grinding (mill density) circuit. The SCADA host computer provides a unified interface: operators view live process diagrams showing motor currents, crusher status, pulp densities and pressure. Automatic control loops maintain steady crusher feed and regulate mill water addition to hold target density. The control room (2 people per shift) uses video surveillance on critical equipment and relies on automated alerts for deviations. This architecture “locks in”operational parameters and has achieved very stable throughput, higher concentrate grades and lower downtime than a manual plant would.

Morocco Silver Plant (500 t/d): Xinhai’s comprehensive automation was also deployed at a 500 t/d silver beneficiation plant in Morocco. Here too, a central control room supervises the entire flotation operation. The plant runs unmanned on-site: only two operators per shift are needed for maintenance and shift changes. Xinhai’s system ties together flotation cell air flow controls, reagent dosing pumps, and level valves so that ore mix and froth levels remain optimal. Continuous digital instrumentation ensures that process data (e.g. concentrate assay, tailings clarity) are visible at the click of a button. The client reports that the plant has run smoothly under Xinhai’s automation for over two years with very high uptime.

These and other deployments (e.g. in Ghana, Guinea, Mongolia, etc.) demonstrate that Xinhai automation is versatile across commodities. In every case, the result has been improved efficiency and reduced labor costs. For instance, many of these automated plants operate continuously with only periodic inspections, whereas traditional plants would require manual adjustments around the clock. Remote monitoring also allows Xinhai’s engineers to diagnose issues from afar, reducing maintenance response time.

Benefits of Xinhai Automation

By integrating its automation products with its engineering services, Xinhai offers several key advantages:

Online Data and Centralized Control: All production data (flow rates, grades, equipment status) are collected and analyzed in real time. Centralized DCS/SCADA and cloud-based dashboards mean that management can make data-driven decisions on the fly. This leads to faster reaction to process upsets and better planning.

Enhanced Safety and Lower Staffing:With remote-controlled equipment and automated safety interlocks, critical areas like crushers, mills and tailings pumps require little or no manual presence. As Xinhai notes, this “unattended” operation model cuts workforce needs and reduces accident risk. Daily labor is largely limited to inspection tours and preventive maintenance.

Tight Integration with Plant Technology: Because Xinhai also supplies the hardware (crushers, mills, pumps,etc.), their automation is designed in tandem with mechanical design. This ensures control loops match the plant’s unique needs and that installation/commissioning are streamlined. In effect, the automation is custom-tailored from design through startup, giving clients confidence in achieving target throughput.

Overall, Xinhai’s automated solutions represent a complete “smart mine” offering. By combining process control systems, Internet-of-Things sensors and cloud analytics, they transform conventional plants into advanced digital facilities. Mines get not only modern equipment but also the brains to run it optimally.

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat