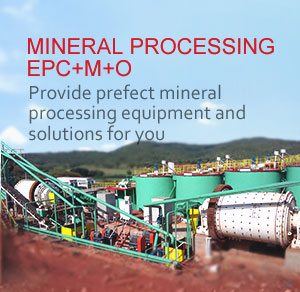

Founded in 1997, Shandong Xinhai Mining Technology Equipment Co., Ltd. is headquartered in Yantai, Shandong, China, and is a global leader in Mine EPCM+O Service. Xinhai provides EPCM+O services for the entire mining industry chain, covering mineral processing tests, mining & processing plant & tailings pond mine design, equipment manufacturing, civil construction, equipment installation and commissioning, and mine management and operation. We employ more than 500 staff members, with two production bases located at our headquarters plant and the Intelligent Equipment Industrial Park. , additionally, with overseas offices in Ghana, Zimbabwe, Tanzania, Peru, and other countries. Its business covers more than 100 countries and regions around the world, serving nearly 2,000 mines and completing more than 500 EPCM+O projects.

"Providing the best solution for your mine" of Xinhai's business philosophy, through technological innovation and customized services, it ensures that the mine achieves efficient, energy-saving and environmentally friendly production goals. Since its establishment, Xinhai has established its position in the industry through a series of milestone events, such as the completion of the Fuchang silica sand project of Korean Glass in 2001 and the acceptance of the large gold mine EPC project of Mongolia Dadi Company in 2003, marking the beginning of its internationalization process. These achievements have made Xinhai a trusted partner of mining companies around the world.

Qualifications

Xinhai Mining has won many international and domestic certifications and honors for its excellent technology and services. The company has passed ISO9001:2015 international quality management system certification, intellectual property management system certification, EU CE certification, and laboratory certification of the China National Accreditation Service for Conformity Assessment (CNAS). In addition, Xinhai also has the Class-A Qualification for General Contracting of Mine Construction (a necessary qualification for mining civil engineering), independent import and export rights, and foreign contracting qualifications. It is a member unit of the China Mining Association and the vice chairman unit of the Gold Mine Technology Innovation Strategic Alliance.

In addition, Mr.Yunlong Zhang, Chairman of Xinhai, is a fellow of the Australian Institute of Mining and Metallurgy (AusIMM) and has the right to sign internationally recognized mining technical reports, further demonstrating the company's authority in the field of technology.

Main Business

Xinhai Mining provides a full range of mining services, covering the following main businesses:

1. Mineral processing tests

Xinhai has its own mining research institute, which can accurately test more than 70 kinds of minerals. By analyzing the physical and chemical characteristics of the ore, Xinhai designs the best mineral processing technology for customers to ensure efficient recovery. For example, for low-grade gold mines, Xinhai adopts the full mud cyanidation process, while for complex polymetallic ores, it maximizes the utilization of resources through a combination of flotation and magnetic separation.

.jpg)

2. Mining & Processing & tailings pond design

Xinhai provides comprehensive mine design services, including mining design, processing plant design, and tailings pond design. The company pays attention to environmental protection and safety, and adopts advanced tailings dry discharge technology to reduce environmental pollution and improve resource utilization. We are considered as one of the earliest companies in China to achieve tailings dry discharge at the world level.

Xinhai has two modern production bases, including the headquarters plant and the intelligent equipment industrial park. Equipped with advanced mining production equipment, it has the production capacity of large-scale mining equipment (a daily production capacity of 50,000 t/d, and the maximum ball mill can produce 7m), and produces a variety of mining equipment, including ball mills, flotation machines, thickeners, agitation tanks, and slurry pump etc. Xinhai also provides equipment procurement and packaging and transportation services to ensure that the equipment is delivered on time and meets project requirements.

4. Civil construction and equipment installation and commissioning

Xinhai is responsible for the civil construction of mining, beneficiation plants and tailings ponds, covering plant construction and equipment infrastructure construction, and provides equipment installation and commissioning services. The company strictly follows international standards to ensure that all facilities and equipment are in optimal operating condition. For example, in the 1,200 tons/day gold mine project in Tanzania, Xinhai employees overcame the challenges of high temperatures and resource shortages in the local area and completed the installation and commissioning work efficiently.

5. Mine management and operation

Xinhai provides mining operation contracting and long-term management services to help customers optimize production processes, reduce operating costs and improve efficiency. Through automated control systems and professional technical teams, Xinhai ensures that mines operate stably and achieve expected production capacity.

.png)

Xinhai Ore Dressing Technology

Xinhai Mining is at the forefront of mineral processing technology, with more than 100 patented technologies applicable to a variety of minerals such as gold, copper, lead-zinc, iron, quartz, lithium etc. The company is able to process complex and difficult-to-process ores, such as high-clay content ores ores with polymetallic paragenesis, and achieve efficient recovery through customized process design.

• Gold ore: Xinhai has developed full-slime cyanidation process, flotation process and gravity separation process, which are suitable for low-grade gold mines and complex gold mines. For example, the full-slime cyanidation process uses activated carbon adsorption and desorption electrolysis technology to efficiently extract gold from low-grade ores.

• Copper ore: Xinhai adopts flotation technology and designs differentiated flotation processes according to ore characteristics (such as porphyry type and skarn type). For example, in the 500 tons/day copper mine project in Myanmar, Xinhai significantly improved the recovery rate of copper concentrate through preferential flotation and magnetic separation processes.

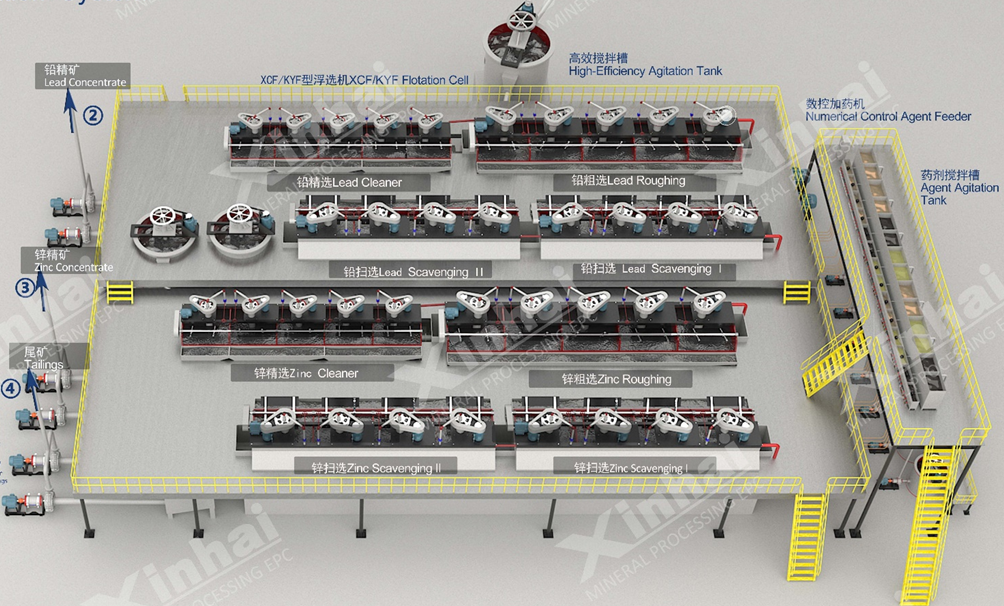

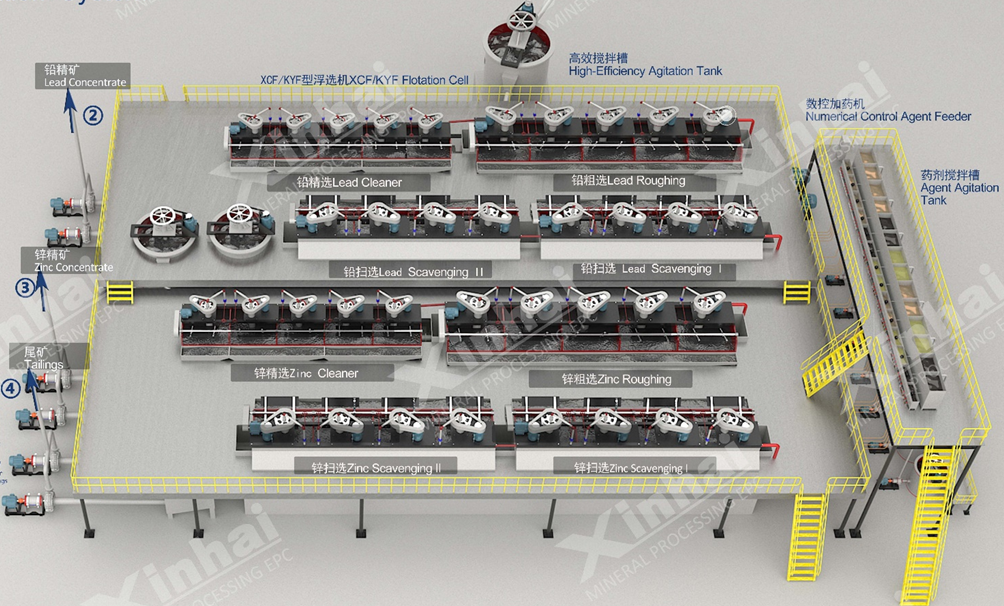

• Lead-zinc ore: For polymetallic ores, Xinhai uses sequential flotation or mixed flotation processes to recover copper, lead, zinc and other metals respectively to ensure comprehensive utilization of resources.

• Iron ore: Xinhai has developed a staged grinding-gravity separation-magnetic separation-reverse flotation process for hematite and magnetite. For example, in a hematite project, Xinhai achieved a concentrate grade of 65.95% and a tailings grade of only 10.05%.

• Quartz (silica sand): Xinhai produces high-purity silica sand through washing, screening and magnetic separation processes to meet high-end needs such as the glass industry.

Xinhai's innovative technologies, such as dry tailings discharge and high-efficiency flotation equipment, significantly reduce mineral processing costs and improve recovery rates, especially when processing difficult-to-separate ores.

Large overseas projects

Xinhai Mining has completed several landmark projects around the world, demonstrating its technical strength in different mineral types and regions. The following are five of its overseas projects:

1. Guinea 15,000 t/d gold processing plant

This project is one of the largest gold concentrators in Africa, located in Guinea, and is divided into the East and West Zones. Xinhai's full mud cyanidation process was used. Through the advanced desorption electrolysis system, the project achieved a high gold recovery rate, and the customer was highly satisfied with the results. Xinhai's engineering team overcame local resource shortages and climate challenges to ensure that the project was delivered on time.

2. Mongolia 3,500 t/d iron ore mining and processing plant

In Mongolia, Xinhai designed and built a processing plant for customers to process magnetite and hematite. It was adopted stage grinding, magnetic separation and reverse flotation processes to produce high-grade iron ore concentrate, meeting customers' needs for product quality and production capacity.

3. Pakistan 1,500 t/d copper processing plant

The project is located in Pakistan and used efficient flotation technology to process copper ore. Xinhai had improved copper recovery and reduced production costs through personalized design and automated control systems, and the project has been running stably so far.

4. Mexico 1500 t/d copper, lead, zinc and polymetallic ore dressing plant

Xinhai provided a comprehensive solution for processing copper, lead, zinc, gold and silver polymetallic ores for Mexican customers. Through the sequential flotation process, the project achieved efficient separation and recovery of various metals, with a comprehensive recovery rate of more than 90%.

5. South Korea silica sand project

In 2001, Xinhai completed the silica sand dressing plant project for South Korea Glass Fuchang Company to produce high-purity silica sand for glass manufacturing. The project adopted washing, screening and magnetic separation processes, becoming a milestone in China's silica sand and quartz sand industry.

Xinhai Mining has become a leader in mineral processing and equipment manufacturing with its advanced technology, comprehensive services and global project experience. By providing customized EPCM+O services, Xinhai helps customers solve problems such as budget overruns and construction delays to ensure efficient and environmentally friendly operation of mines. Whether it is difficult-to-select or rare ores such as gold, copper, lead-zinc, iron or quartz, Xinhai can provide innovative solutions to help the development of your mine better.

.jpg)

.png)

zz540045886@gmail.com

zz540045886@gmail.com Chat

Chat